Electric Automatic Capsule Filler With 12 Mois de garantie

Detailed Product DescriptionName:NJP 1200 Automatic Control Capsule Filling Machine ManufacturerAfter-sales Service Provided:Ingénieurs disponibles pour entretenir les machines à l’étranger,Support technique vidéo,Online SupportCapacity:72000 Capsules/hourVoltage:220V/380V 50HzDimension(l*w*h):900*870*1950mmCondi…

- Livraison estimée : 7 Jours de livraison rapide

- Certification : cGMP CE ISO SGS et etc.

- Service après-vente assuré : Ingénieurs disponibles pour entretenir les machines à l’étranger.

| Description détaillée du produit | |||

|---|---|---|---|

| Nom: | NJP 1200 Automatic Control Capsule Filling Machine Manufacturer | ||

| Service après-vente fourni: | Ingénieurs disponibles pour entretenir les machines à l’étranger,Support technique vidéo,Assistance en ligne | ||

| Capacité: | 72000 Capsules/hour | ||

| Tension: | 220V/380V 50Hz | ||

| Dimension(l*w*h): | 900*870*1950mm | ||

| Condition: | New | ||

| Automatic Grade: | Automatic | ||

| Poids: | 1100KG | ||

| Type: | Filling Machine | ||

| Garantie: | 12 Months | ||

| Pouvoir: | 5.5kw | ||

| Driven Type: | Electric | ||

| Souligner: |

remplisseuse de capsules automatique, pill filler machine |

||

NJP 1200 Automatic Control Capsule Filling Machine Manufacturer

Introduction of capsule filling machine:

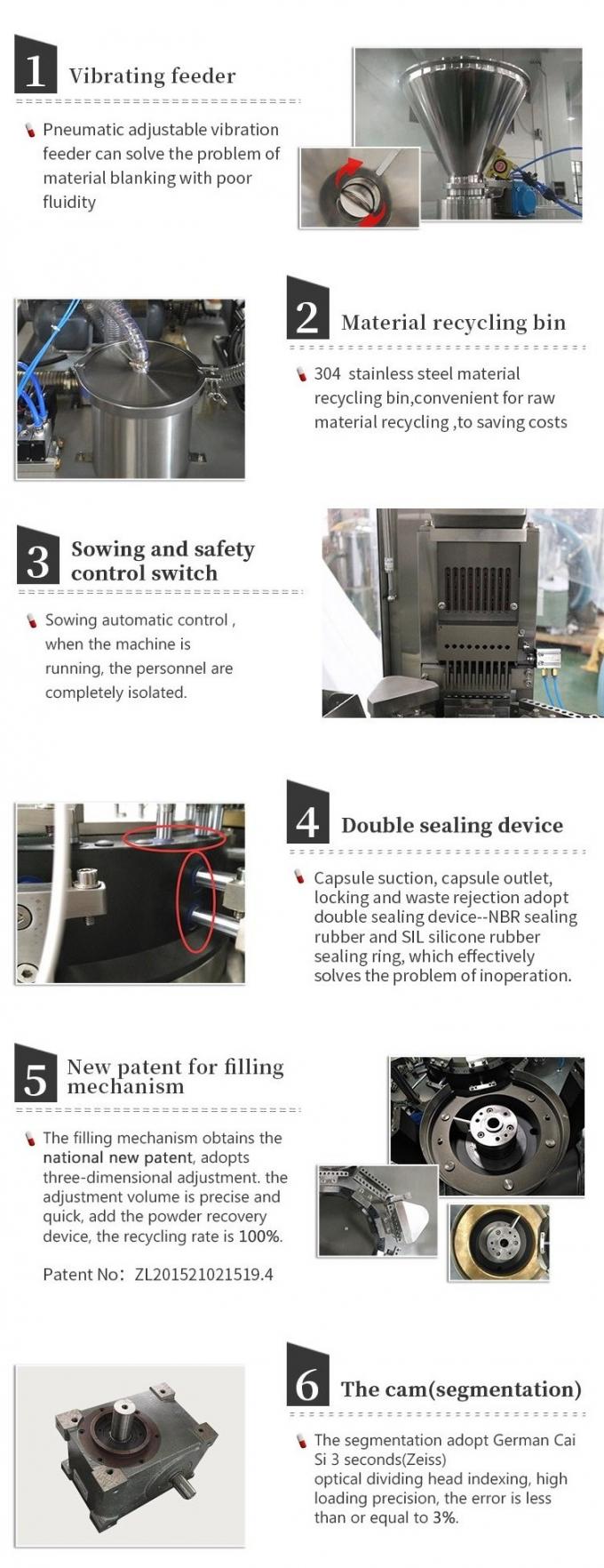

The filling speed of the capsule filling machine is fast, and the difference of the size of the capsule filling machine is small. The filling of the capsule shell, the capsule cap finishing, and the capsule set are integrated, which is compact and convenient. In addition, the capsule filling machine has many advantages such as high speed, high efficiency, simple operation, convenient maintenance and low power consumption. It is the preferred capsule filling (filling) machine for pharmaceutical factories, health care products factories and hospital preparation rooms.

Features of capsule filling machine:

1.This pharmaceutiacl automatic capsule filling meets the GMP requirements, it is an ideal equipment for filling Chinese, Western medicines and health care product .

2.This automatic capsule fill machines can automatically finish the production process including sowing, capsule separating, filling, locking, unqualified capsule rejected and finished products output.

3.This pharmaceutical capsule filling machine has safety firs, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

4. Guangdong Rich Packing Machinery Co.. Ltd.'s capsule filler machine deploy segmentation adapt German Cai Si for 3 secondes (Zeiss) indexation de la tête de division optique, l'arbre d'indexation a effectué un traitement unique, chargement et haute précision,

l'erreur est inférieure ou égale à 3%.

5.The capsule filler machines use the imported SIL silicone rubber sealing ring to block the powder into the bearing, which effectively solves the problem of the card machine that the powder enters the bearing.

| Description détaillée du produit | |||

|---|---|---|---|

| Capacité de production | 72000 pièces/h | ||

| Poids net de la machine | 1100Kilogrammes | ||

| Taille globale de la machine | 900×870×1950 | ||

| Pouvoir | 380/220V 50 Hz | ||

| Puissance totale | 5.5KW | ||

| Nombre d'alésages de segment | 9 | ||

| Vide | 40m3/heure-0.04-0.08Mpa | ||

| Collecteur de poussière | 24.5Kpa 210m3/h | ||

| Bruit | <75Base de données(UN) | ||

| Taux de réalisation | Capsule vide 99.9% Capsule complète 99.8% | ||

| Capsule applicable | 00,0,1,2,3,4,5# | ||

| Erreur de remplissage | Médecine occidentale:±3% Médecine chinoise:±4% | ||

| Produit applicable | Pouvoir,granule,pastille,comprimé | ||

| Poids | 1100Kilogrammes | ||

| Packing size | 1490×1260×2150mm | ||

6.equipped with on-line air pressure die cleaning system, the upper and lower dies are clean and without dust, improve the sowing effect.

The capsule filler machinery is precision mold concentricity, zero deviation, ensure that the capsule is not wiping, no damage.

7.Automatic rejection device, improve the charging efficiency ,the capsule filling equipment is suitable to pharmacy and health care food manufacture.

8.The control of capsule filler machine appliance adopts the world famous brand, modularized setup, convenient inspection and maintenance, SIEMENS human machine interface, real-time counting, and can print the equipment according to customer needs, print production date, batch number, code, etc..

8.Votre machine peut-elle bien répondre à nos besoins?

Nous vous fournirons une proposition quant à votre besoin spécifique, and each machine is customized to satisfy customer's need well.

9.What's your payment way?

T/T by our bank account directly, or L/C, or by the West Union, or in cash.

10.Rotary of capsule filling machine design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow

pollution