Dpp 160L Liquid Pack Blister Packaging Machine , Liquid Filling And Sealing Packing Machine

Detailed Product DescriptionBlister Pack Machine Product:Dpp 160 Liquid Blister Pack Packaging Machine,Liquid Filling And Sealing Packing MachineBlister Pack Machine Blanking:10??35 Times/minProduction Capacity:1200-4200 Plates/hMax. Shaping Dia. And Depth:145*110*15mm Max. Depth 26mm??custom-made??St…

- Entrega estimada : 7 Días de entrega rápida

- Proceso de dar un título : cGMP CE ISO SGS y etc.

- Servicio posventa proporcionado : Ingenieros disponibles para dar servicio a maquinaria en el extranjero..

| Descripción detallada del producto | |||

|---|---|---|---|

| Blister Pack Machine Product: | Dpp 160 Liquid Blister Pack Packaging Machine,Liquid Filling And Sealing Packing Machine | ||

| Blister Pack Machine Blanking: | 10??35 Times/min | ||

| Capacidad de producción: | 1200-4200 Plates/h | ||

| máx.. Shaping Dia. And Depth: | 145*110*15mm Max. Depth 26mm??custom-made?? | ||

| Standard Travel Range: | 50??120milímetros | ||

| Standard Plate: | 80*57milímetros | ||

| Power OfMain Motor: | 1.5kW | ||

| Blister Packing Machine Power: | 380V/220V/50Hz | ||

| Blister Package Machine Noise: | <75dBA | ||

| Thickness And Width Of PVC: | 0.15??0.5*150milímetros | ||

| Thickness And Width Of PTP: | 0.02??0.035*150milímetros | ||

| Destacar: |

160L Blister Packaging Machine, 0.6MPa Sealing Packing Machine |

||

dpp 160L liquid pack blister packaging machine,Liquid Filling And Sealing packing Machine

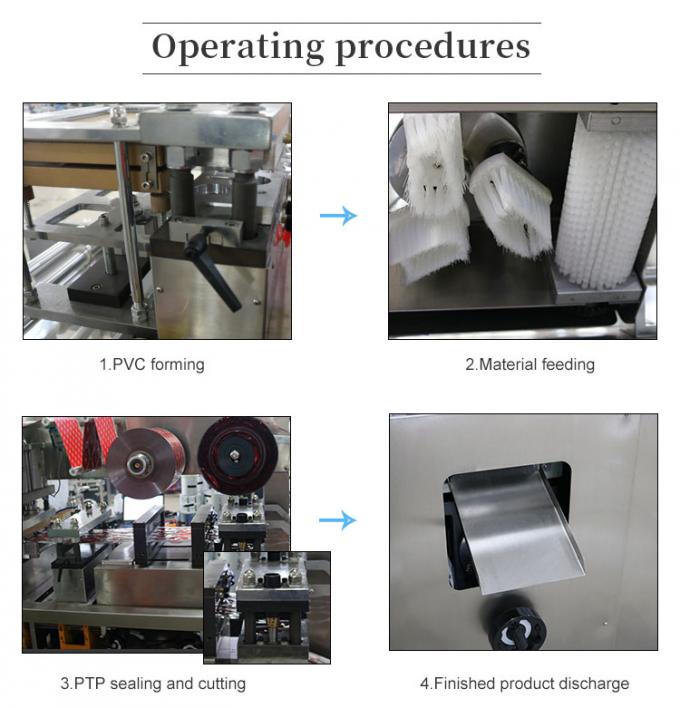

DPP-160L is a high-speed flat-panel aluminum-plastic liquid blister packaging machine from Guangdong Rich Packing Machinery Co.,Ltd. It can pack liquid such as yoghurt,oil,jam,butter,honey,cheese,sauce,cream or perfume ect.with possessing fully automatic shaping,adding,sealing and blanking.

| Descripción detallada del producto | |||

|---|---|---|---|

| Blanking | 10??35 times/min | ||

| Capacidad de producción | 1200-4200 plates/h | ||

| máx.. Shaping Dia. And Depth | 145*110*15mm Max. Depth 26mm(custom-made) | ||

| Standard Travel Range | 50??120milímetros | ||

| Standard Plate | 80*57milímetros | ||

| Power ofMain Motor | 1.5kW | ||

| Total Power | 3.8kW | ||

| Power | 380V/220V/50Hz | ||

| Vacuum | 0.4MPa-0.6MPa | ||

| Noise | <75dBA | ||

| Thickness and Width of PVC | 0.15??0.5*150milímetros | ||

| Thickness and Width of PTP | 0.02??0.035*150milímetros | ||

| Dialyzing Paper | 50??100g*150mm | ||

| Mold Cooling | Runing water or circulating water | ||

| Peso | Net weight 850 kilos ;Gross weight1400 kg | ||

| Overall Size of Machine | 2300*635*1500 milímetros | ||

| Tamaño de embalaje | 2750*950*1800milímetros | ||

1.liquid feeding device

easy to feed liquid state product Smoothly

2. Brake motor

Motor with braking function,accurate operation journey, during the debugging process, the mold runs to the highest point, will not turn, easy to adjust.

3. Chain drive position

Strand chain transmission, low noise.lower than 75dBA.

4. Proximity switch

Molding, traction, positioning module using proximity switch control instead of pneumatic control, higher accuracy, longer service life.

5.Heating and anti scalding station:prevent scalding during operation.

6.Heat sealing device

accurate operation and easy operation

7.Cursor version