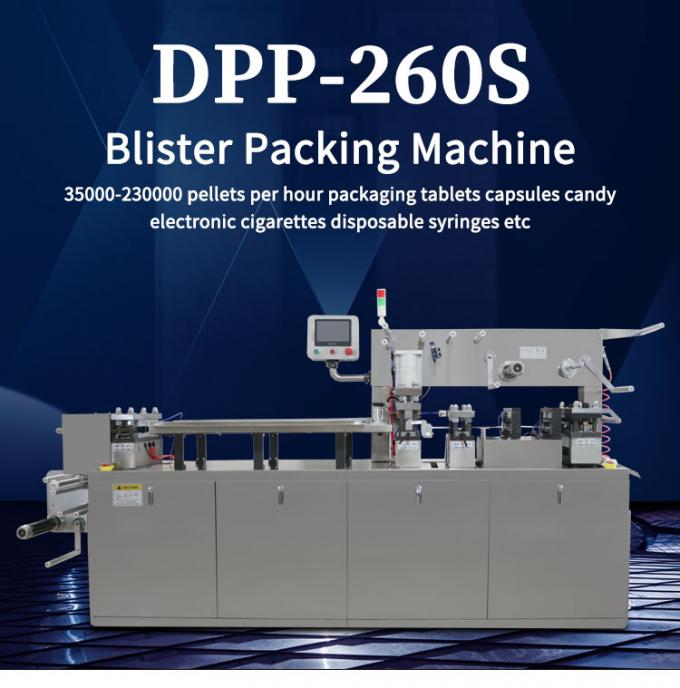

380V Automatic Tablet Capsule Pill Blister Packing Machine High Speed

Khả năng mô tả sản phẩm chi tiết:230000 Pellets Per HourMax. Shaping Dia. And Depth:240*170*15mm Max. Depth 26mm??custom-madeBlanking:45 Times/minPower Of Main Motor:1.5kWTotal Power:6.2kWHighlight:pill blister pack machine, tablet blister packing machineDPP-260S is a high-speed flat-p…

- Ước tính giao hàng : 7 Ngày giao hàng nhanh chóng

- Chứng nhận : cgmp ce iso sgs và vv

- Sau bán hàng được cung cấp : Các kỹ sư có sẵn cho máy móc dịch vụ ở nước ngoài.

| Mô tả sản phẩm chi tiết | |||

|---|---|---|---|

| Năng lực sản xuất: | 230000 Pellets Per Hour | ||

| Max. Shaping Dia. And Depth: | 240*170*15mm Max. Depth 26mm??custom-made | ||

| Blanking: | 45 Times/min | ||

| Power Of Main Motor: | 1.5kW | ||

| Total Power: | 6.2kW | ||

| Điểm nổi bật: |

pill blister pack machine, tablet blister packing machine |

||

DPP-260S is a high-speed flat-panel aluminum-plastic blister packaging machine newly developed by Guangdong Rich Packing Machinery Co.,Ltd. It is driven by servo motor, with better accuracy, stable operation and convenient adjustment.DPP-260S expect can packaging tablets,viên nang,candy,also can packaging many big sizes products,such as electronic cigarettes,perfume,tomato paste,Viên nang mềm,big honey pills,penicillin bottles and etc.

| Mô tả sản phẩm chi tiết | |||

|---|---|---|---|

| Power supply | 380V/220V/50Hz | ||

| Standard Travel Range | 40??185mm | ||

| Standard Plate | 80*57mm | ||

| Thickness and Width of PVC | 0.15??0.5*120mm | ||

| Thickness and Width of PTP | 0.02??0.035*120mm | ||

| Dialyzing Paper | 50??100g*120mm | ||

| Vacuum | 0.4MPa-0.6MPa | ||

| Tiêu thụ khí | ≥0.3m3/min | ||

| Noise | <75dBA | ||

| Mold Cooling | Runing water or circulating water | ||

| Cân nặng | Net weight1300kg ;Gross weight1400kg | ||

| Overall Size of Machine | 3000*730*1600 mm(L*W*H) | ||

| Packing Size | 2750*950*1800mm(L*W*H) | ||

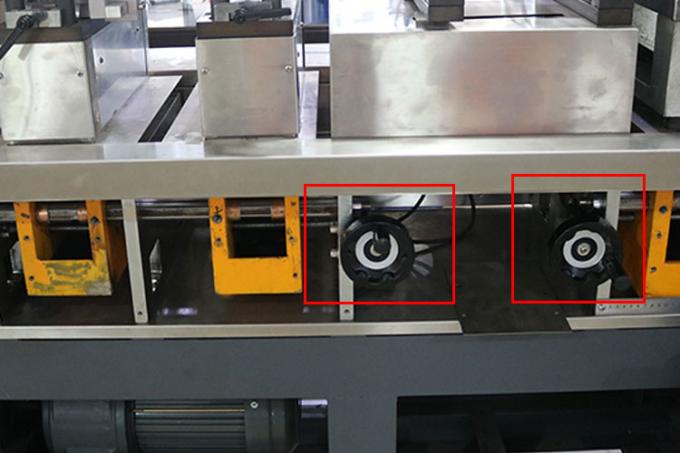

1.Cylinder Drive Heat Sealing Device

Adjustable temperature, Accurate Travel??Tight Sealing, No Wrinkles

2.Handwheel With Scales

Each Station Can Move Freely On The Spindle Through The Free Adjustment Of Handwheel

3.Locating Slot Pins Mould

One-key Positioning, And The Debugging Time Was Reduced 50%