NJP-1500D Fully Automatic PLC Control Capsule Filling Machine

Detailed Product DescriptionApplication:Fill The Power , Pette, GranuleCapsule Size:00,0,1,2,3,4,5#Üretim kapasitesi:90000pcs/hoursTotal Power:5.5KWMachine Size:900??870??1950mmPacking Size:1490??1260??2150mmhighlight:PLC Control Capsule Filling Machine, Fully Automatic Capsule Filling Machine, 5.5KW …

- Tahmini Teslimat : 7 Günler Hızlı Teslimat

- Sertifika : CGMP CE ISO SGS ve vb.

- Satış sonrası sağlanan : Mühendisler Yurtdışında hizmet makineleri için mevcut.

| Ayrıntılı ürün açıklaması | |||

|---|---|---|---|

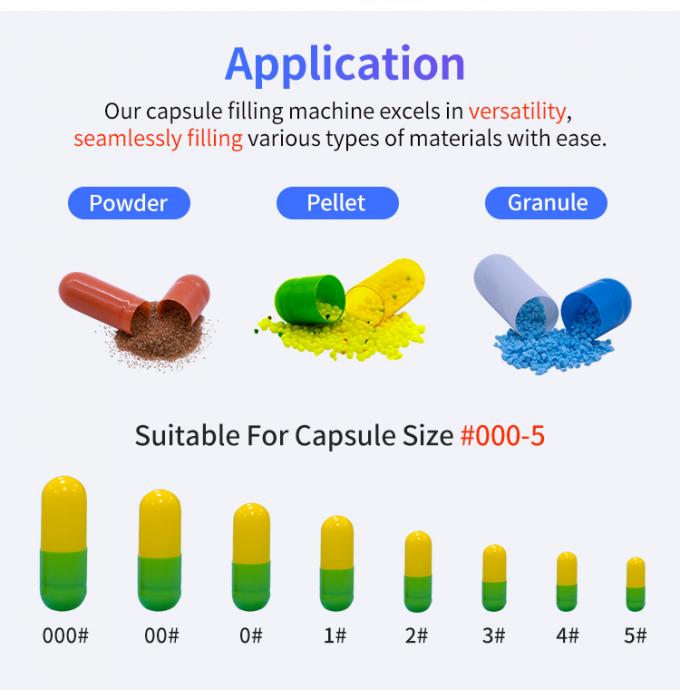

| Başvuru: | Fill The Power , Pette, Granule | ||

| Kapsül boyutu: | 00,0,1,2,3,4,5# | ||

| Üretim kapasitesi: | 90000pcs/hours | ||

| Total Power: | 5.5KW | ||

| Machine Size: | 900??870??1950mm | ||

| Packing Size: | 1490??1260??2150mm | ||

| Vurgulamak: |

PLC Control Capsule Filling Machine, Fully Automatic Capsule Filling Machine, 5.5KW Capsule Filling Machine |

||

The Main Feature of NJP-1500D Capsule Filling Machine

1. Advanced Technological Innovations

– The NJP-1500D model features 7 major technological innovations and holds 2 invention patents. It is capable of filling powder, granules, and other materials into a wide range of capsule sizes (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#).

2. High Efficiency and Precision

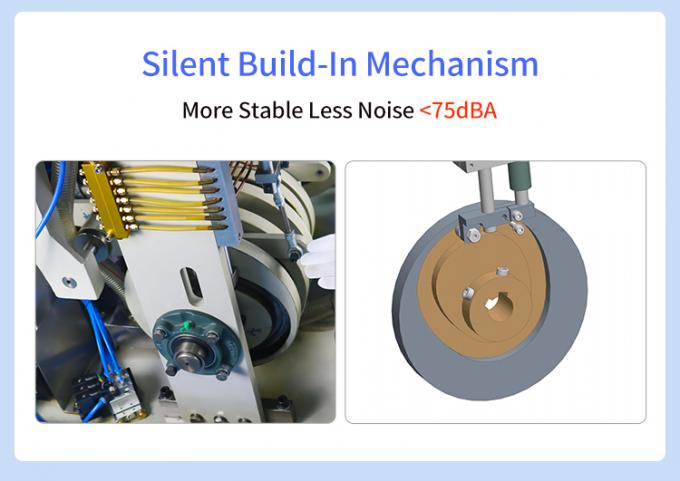

– The machine boasts a production capacity of 90,000 capsules per hour, with high accuracy in filling (±3% for Western medicine and ±4% for Chinese medicine). It ensures a making rate of 99.9% for empty capsules and 99.8% for filled capsules, with an overall noise level below 75DB(A).

3. Ease of Maintenance and Operation

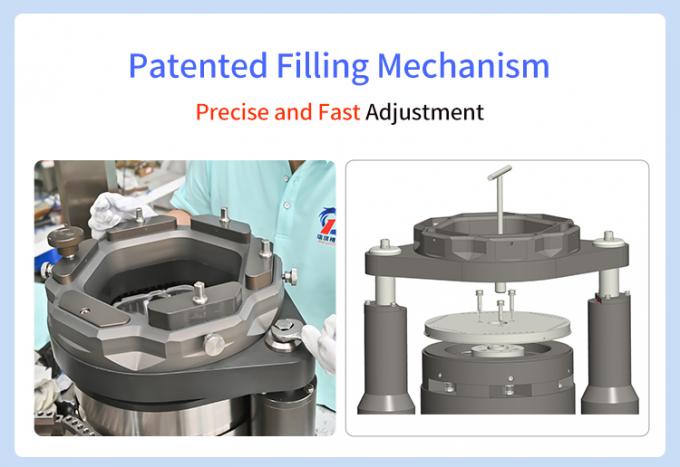

– Designed with a low platform, modular structure, and easy-to-operate interface, the NJP-1500D also features an intelligent lubrication system and a patented rotary design that simplifies maintenance and reduces downtime.

4. Safety and Compliance

– The machine is designed with safety in mind, including features like door control and emergency stop switches. It meets GMP and CE standards, ensuring compliance with industry regulations. All parts in contact with the drug are made of stainless steel 316.

5. Advanced Control and Customization

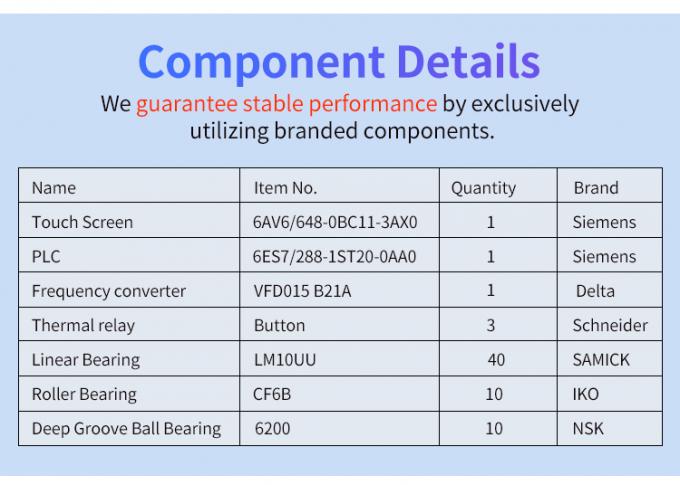

– The control system uses world-renowned brands such as Siemens and Schneider, featuring a high-degree PLC touch screen for integration and real-time monitoring. It offers customizable options for printing production dates, batch numbers, and other details according to customer needs.

3 Reasons to Consider Buying the NJP-1500D Fully Automatic Capsule Filling Machine

1. Advanced Technological Innovations

The NJP-1500D capsule filling machine boasts 7 major technological innovations and 2 invention patents. This advanced design allows for precise and versatile filling of various capsule sizes (000# to 5#) with different materials such as powder, granules, pellets, and tablets. The machine ensures accurate loading, stable operation, and minimizes dust, meeting GMP and CE standards. These features make it ideal for producing Chinese and Western medicines, as well as health care products.

2. High Efficiency and Low Maintenance

The NJP-1500D model is designed for high production efficiency, capable of producing up to 90,000 capsules per hour. It includes features like a rotary design with imported SIL silicone rubber for effective sealing and a dust-free environment, as well as a high-precision cam indexing box to ensure smooth and reliable operation. Additionally, maintenance is straightforward with an intelligent lubrication system and modular components that allow for quick and easy maintenance and mold changes, enhancing overall productivity and reducing downtime.

3. Safety and User-Friendly Design

Safety is a top priority in the NJP-1500D design. The machine includes comprehensive safety features such as door control systems and emergency stop switches, ensuring the safety of the operators. The user-friendly design features a Siemens touch screen interface for easy operation and real-time monitoring, modular structure for easy operation, and convenient maintenance. This ensures not only a high degree of operational safety but also an intuitive and efficient user experience.

| Ayrıntılı ürün açıklaması | |||

|---|---|---|---|

|

How to Contact Us? |

|||

|

E -posta |

yönetici@richpacking.cn | ||

|

WhatsApp & WeChat |

+86-138-2609-3596 | ||

|

Visit WebSite |

www.richpacking020.com | ||