RQ-120W Kartonlama Paketleme Makinesi Otomatik Yüksek Hızlı Tıbbi Kozmetik Maske

Detailed Product DescriptionName:Automatic Automatic Carton Packing Machine / Machinery Automatic CartoningSpeed:30-120 Carton/minTotal Power:0.750 KWSize Range Of Carton:L(70-185)*W(35-90)*H(14-50)mmRange Of Folding Times Of Instructions:1-4 FoldPower Supply:220/380V 50HzCarton Weight:250-350g/?OP…

- Tahmini Teslimat : 7 Günler Hızlı Teslimat

- Sertifika : CGMP CE ISO SGS ve vb.

- Satış sonrası sağlanan : Mühendisler Yurtdışında hizmet makineleri için mevcut.

| Ayrıntılı ürün açıklaması | |||

|---|---|---|---|

| Name: | Automatic Automatic Carton Packing Machine / Machinery Automatic Cartoning | ||

| Speed: | 30-120 Carton/min | ||

| Total Power: | 0.750 KW | ||

| Size Range Of Carton: | L(70-185)*W(35-90)*H(14-50)mm | ||

| Range Of Folding Times Of Instructions: | 1-4 Fold | ||

| Güç kaynağı: | 220/380V 50Hz | ||

| Carton Weight: | 250-350g/?O | ||

| Pressure Intensity: | ??0.6MPa | ||

| Overall Size Of Machine: | 3100*1100*1550?L | ||

| Net Weight Of Machine: | 1600kg | ||

| Vurgulamak: |

Otomatik Kartonlama Paketleme Makinesi, High Speed Cartoning Packing Machine |

||

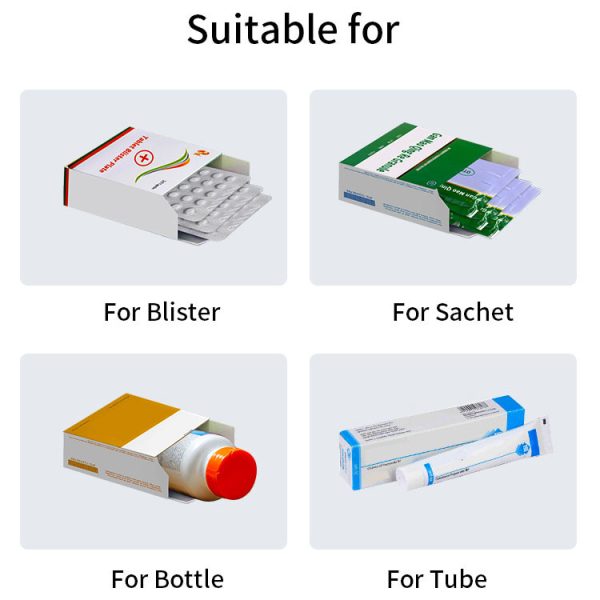

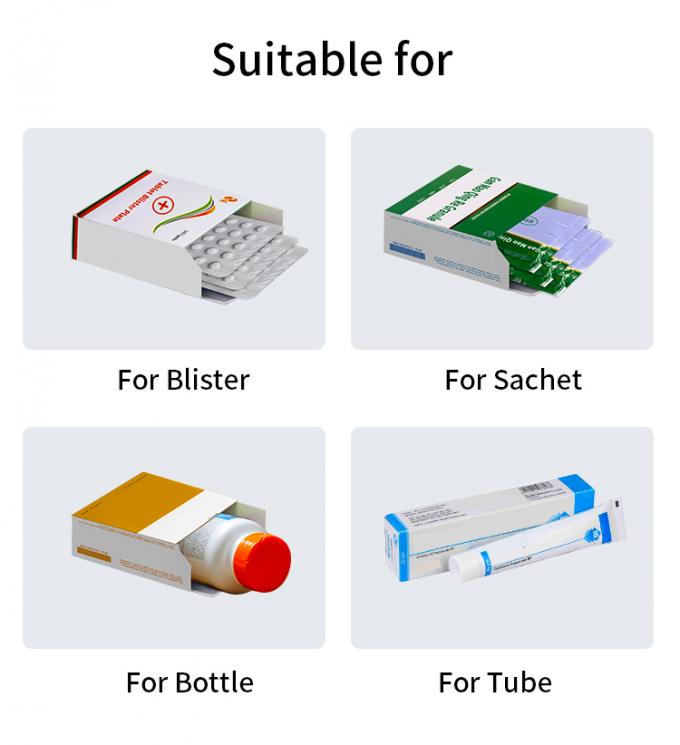

Otomatik Karton Makinesi Ambalaj Puafet Blister Sac Şişe Tüpü

| Ayrıntılı ürün açıklaması | |||

|---|---|---|---|

| carton pack machine Model | RQ-ZH-12OW | ||

| carton machine Speed | MAX 125 cartons/min | ||

| carton pack machine power | 0.750 KW | ||

| Power supply | 110V/220/380V 50Hz | ||

| Requirements of carton | size range of carton:L(70-185)*W(35-90)*H(14-50)mm | ||

| carton weight:250-350g/?O | |||

| Requirements of instructions | size range of instructions:L(78-250)*W(90-170)mm | ||

| range of folding times of instructions:1-4 fold | |||

| instructions weight:60-70g/?O | |||

| carton pack machine Pressure | pressure intensity:≥0.6MPa | ||

| air consumption:120-160 L/dk | |||

| Overall size of machine | 3100*1100*1550?L | ||

| Net weight of machine | about 1600kg | ||

Every carton packaging machinery Pharma be equipped with different feeding device, that is suitable for medicine box packaging , daily use, cosmetics and the other industries, and meet the carton packaging requirements of bottled, bagged, alu pvc plate, the electronic products and other products.

According to the number of each cartons be packed, single or the multiple feeding heads can be using. This is no need to worry about the much missing materials, as in the whole production process, from the initial feeding, the middle opening and the manual folding, to the synchronous entry of many multiple types of materials into the box at the later stage, and the final working of finished products, our company has set up the detection photo electric systems.

These inspection device are centrally distributed in the various workstations, like as the feeder, quantity inspection, packing into the conveyor belts inspection, packaging number inspection, the carton in-situ inspection and etc.. more smooth operation, suitable for 24 hours continuous production.