Fully Auto Capsule Filling Machine , 220V/380V 50Hz Automatic Pill Filler

Detailed Product DescriptionName:Latest Fully Automatic Capsule Filling Machine NJP6000 CE SGS ISOAfter-sales Service Provided:Engineers Available To Service Machinery Overseas,Video Technical Support,Online SupportCapacity:6000 Ccapsules / MinDimension(l*w*h):1500*1250*2200mmWeight:3000KgType:Filli…

- Estimated Delivery : 7 Days Fast Delivery

- Sertifika : cGMP CE ISO SGS and etc

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| Name: | Latest Fully Automatic Capsule Filling Machine NJP6000 CE SGS ISO | ||

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas,Video Technical Support,Online Support | ||

| Capacity: | 6000 Ccapsules / Min | ||

| Dimension(l*w*h): | 1500*1250*2200mm | ||

| Weight: | 3000Kg | ||

| Type: | Filling Machine | ||

| Voltage: | 220V/380V 50Hz | ||

| Condition: | New | ||

| Driven Type: | Electric | ||

| Power: | 11KW | ||

| Automatic Grade: | Automatic | ||

| Warranty: | 12 Momths | ||

| Highlight: |

automatic capsule filler, pill filler machine |

||

Latest Fully Automatic Capsule Filling Machine NJP6000 CE SGS ISO

| Detailed Product Description | |||

|---|---|---|---|

| Production capacity | 360000pcs/h | ||

| Net weight of machine | 3000Kg | ||

| Overall size of machine | 1500×1250×2200mm | ||

| Power | 380V 50Hz | ||

| Total power | 11KW | ||

| No.of segment bores | 43 | ||

| Vacuum | -0.02~0.06Mpa | ||

| Dust collector | Air consumption 0.2m3/min Air pressure 0.3-0.4Mpa | ||

| Noise | <75DB(A) | ||

| Making rate | Empty capsule 99.9% Full capsule 99.8% | ||

| Applicable capsule | 00,0,1,2,3,4,5# | ||

| Filling error | Western medicine:±3% Chinese medicine:±4% | ||

| Applicable product | Power,granule,pellet,tablet | ||

1.Pharmacy capsule filling equipment can fill powder, granules and other materials into hollow capsules (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#).

2.This automatic capsule fill machines can automatically finish the production process including sowing, capsule separating, filling, locking, unqualified capsule rejected and finished products output.

4.The capsule filling machine has the advantages of accurate loading, stable operation and no dust.

5.This pharmaceutiacl automatic capsule filling machine meets the GMP requirements, it is an ideal equipment for filling Chinese, Western medicines and health care product .

6.The capsule filling machine of Guangdong Rich Packing Packing Machinery Co. Ltd. has reasonable design,modular structure, easy operation and lower failure rate.

7.This pharmaceutical capsule filling machine has safety firs, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

8Guangdong Rich Packing Machinery Co. Ltd.'s capsule filler machine deploy segmentation adapt German Cai Si for 3 seconds (Zeiss) optical dividing head indexing, indexing shaft completed a one-time processing, loading and high precision,

the error is less than or equal to 3%.

9.Rotary of capsule filling machine design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow pollution;

Transverse biaxial adapt PTFE oil-less bearing, no need refueling; modular structure, equipped with jog operation, convenient maintenance and cleaning, replacement of mold only 15 minutes,our capsule filling machine is newest.

10.Guangdong Rich Packing Machinery Co. Ltd. has big design deparment of capsule filling machine,the filling mechanism obtains the national new patent, adopts the three-dimensional adjustment, makes the metering plate evenly force, the

adjustment volume is precise and quick, and the powder recovery device is added, the recycling rate is 100%, which reduces the waste and improves the economic benefit.

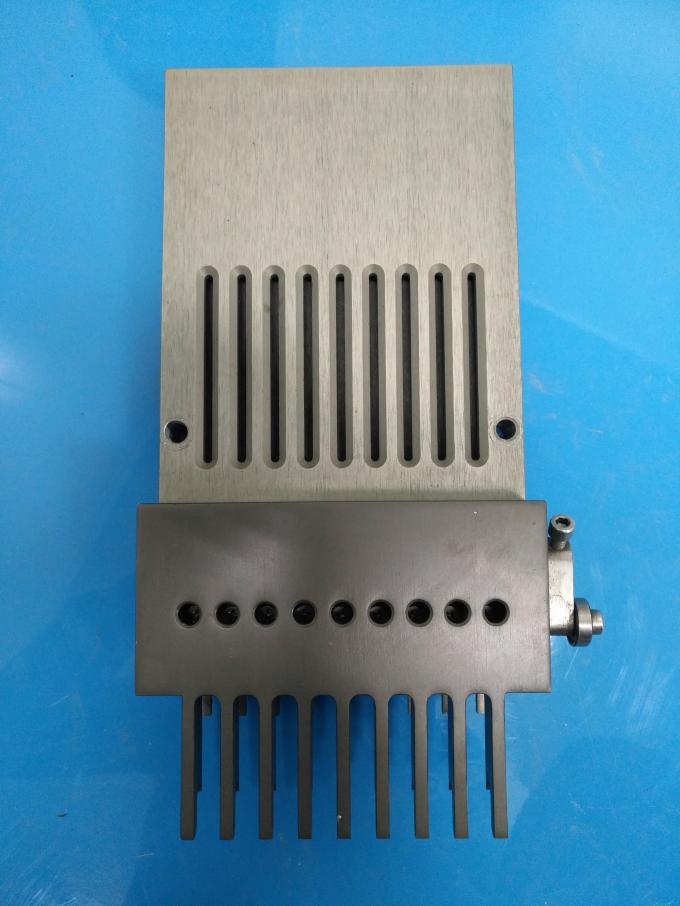

mold of capsule filling machine

mold cabinet of capsule filling machine

1. Material of mold : the capsule is all stainless steel 316L in the upper and lower moulds, and the material is more resistant to corrosion and durability.

2. The filling rod, the upper and lower die holes, the measuring disk adapt non polar electronic polishing treatment, enhance the material fluidity, which has solved the problems of sticky of material, stick with mold and easy to absorb moisture. (According to the material properties and the special requirements of customers, we can provide the Teflon coating processing service)