DPP Automatic Blister Packing Machine Forming Packaging Tablet Capsule Pill

Detailed Product DescriptionProduction Capacity:236,000 Pcs/hourNumber Of Blanking:20??180 Boards/minMaximum Forming Area:160??250*15mmMaximum Depth:26มม. (can Customized)Standard Travel Range:40-160mmStandard Plate:80*57mmPVC Thickness/width:260??0.15-0.45mmPTP Aluminum Foil Thickness/width:260??0.02-0….

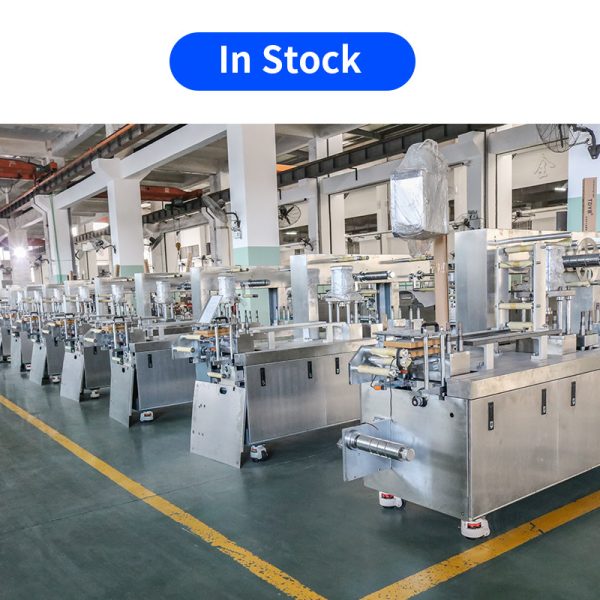

- การจัดส่งโดยประมาณ : 7 วันจัดส่งที่รวดเร็ว

- การรับรอง : CGMP CE ISO SGS และ ETC

- ให้บริการหลังการขาย : วิศวกรที่มีให้บริการเครื่องจักรในต่างประเทศ.

| รายละเอียดผลิตภัณฑ์โดยละเอียด | |||

|---|---|---|---|

| กำลังการผลิต: | 236,000 Pcs/hour | ||

| Number Of Blanking: | 20??180 Boards/min | ||

| Maximum Forming Area: | 160??250*15มม. | ||

| Maximum Depth: | 26มม. (can Customized) | ||

| Standard Travel Range: | 40-160มม. | ||

| Standard Plate: | 80*57มม. | ||

| PVC Thickness/width: | 260??0.15-0.45มม. | ||

| PTP Aluminum Foil Thickness/width: | 260??0.02-0.03มม. | ||

| เน้น: |

Automatic Blister Packing Machine, Capsule Blister Packing Machine, 236000 pcs/ Hour Blister Packing Machine |

||

DPP Automatic Blister Packing Machine Forming Packaging Tablet Capsule Pill

| รายละเอียดผลิตภัณฑ์โดยละเอียด | |||

|---|---|---|---|

| Thickness and Width | 260×0.02 – 0.03มม. | ||

| Dialyzing Paper data | 50??100g*260มม. | ||

| Vacuum of blister packing machine 260R | 0.4MPa-0.6MPa | ||

| gas consumption | ≥0.2m3/min | ||

| Noise of blister packing machine 260R | <75dBA | ||

| Mold Cooling | Runing or circulating water It is recommended to use constant temperature cold water 60 L/H | ||

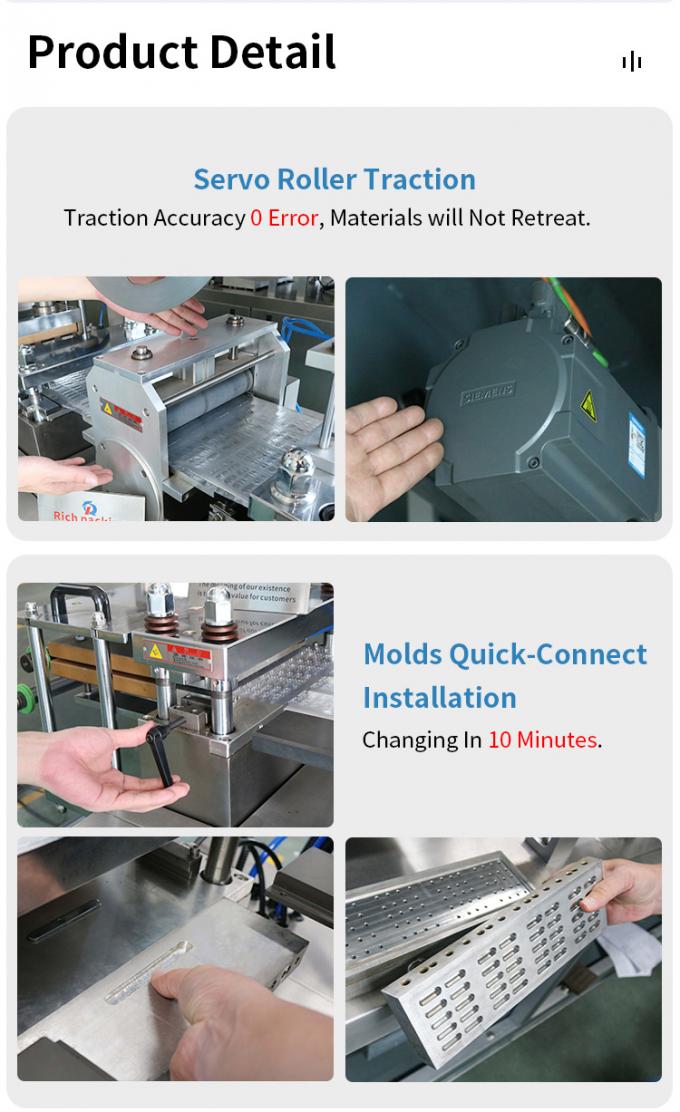

The Blister Packaging Machine Automated we Rich Packing provide long as to 3 years warranty short leading time in ten days, is a most popular machine with a wide range of applications: for as an important parts of the 260r DPP automatic blister packaging machine, the feeding motor and the servo motor are selected from Chinese Taiwan Delta brands. The servo motors have extremely high traction accuracy, and it will be zero error in the traction precision.

Even if the machine stops suddenly, the traction position will not appear to backwards. The operating does not need to be aligned, and the operation is very easy. The PVC material feeding motor has the characteristics of accurate material feeding and fast machinery running speed.

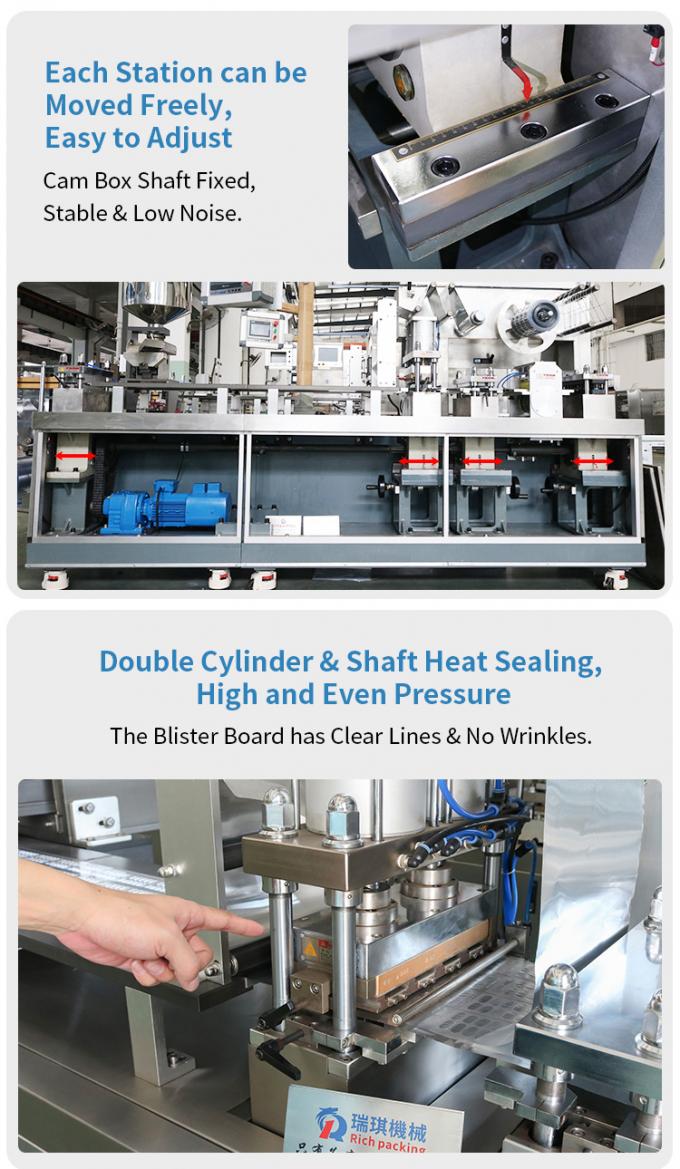

The PLC smart touch screen of the blistering machine automatic is selected from Siemens from Germany, and the module designed is selected from Japan's Omron. The PLC screen and its modules of the blister packaging machine fully automatic are more convenient for data management. At the mean time, it also has a data programming functions, that is convenient for customers to operate and to manage, and has a highly degree of integration.

The emergency stop buttons of the Blister Packaging Machinery Automated is made by France Schneider. When the machinery fails, please press the emergency stop button to stop the machine at once.