High-performance Tablet Press Machine For Pharmaceutical Tablet Production

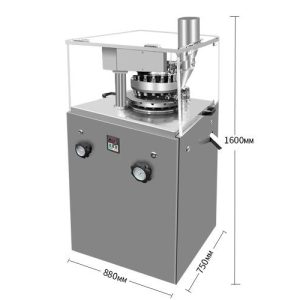

Detailed Product DescriptionMax Production Capacity:110,000pcs/hMax Depth Of Filling:24mmMax Number Of Dies:Max 29 SetsWeight Of Machine:1600kgMax Thickness Of Tablet:12mmMax Diameter Of Tablet:25mmRotational Speed Of Turret:5-21 RpmPower:220/380VHighlight:High Performance Tablet Press, Pharmaceutic…

- Estimated Delivery : 7 Days Fast Delivery

- Certification : cGMP CE ISO SGS and etc

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| Max Production Capacity: | 110,000pcs/h | ||

| Max Depth Of Filling: | 24mm | ||

| Max Number Of Dies: | Max 29 Sets | ||

| Weight Of Machine: | 1600kg | ||

| Max Thickness Of Tablet: | 12mm | ||

| Max Diameter Of Tablet: | 25mm | ||

| Rotational Speed Of Turret: | 5-21 Rpm | ||

| Power: | 220/380V | ||

| Highlight: |

High Performance Tablet Press, Pharmaceutical Tablet Press Machine, High Performance Tablet Press Machine |

||

High-performance Tablet Press Machine for Pharmaceutical Tablet Production

Product Description:

One of the key features of the tablet press machine is its rotational speed of turret, which ranges from 5 to 21 Rpm. This means that the machine is capable of producing a large number of tablets in a relatively short period of time, making it an efficient and cost-effective option for pharmaceutical manufacturers.

The tablet press machine also boasts a maximum number of dies of 29 sets, which further increases its production capacity. With a maximum production capacity of 110,000pcs/h, this machine is ideal for high-volume pharmaceutical production lines where efficiency and speed are of the utmost importance.

The material of the die used in the tablet press machine is GCr15, a high-quality material that ensures the longevity and durability of the machine. This material is known for its strength and resistance to wear and tear, making it an ideal choice for use in a pharmaceutical setting.

The tablet press machine is also designed with power in mind, offering both 220V and 380V options to suit the needs of different production facilities. This ensures that the machine can be integrated seamlessly into existing power systems, without the need for costly and time-consuming modifications.

In summary, the Tablet Press Machine is a high-quality, efficient, and versatile pharmaceutical tablet press that is capable of producing a wide range of tablets, including effervescent tablets. With its high rotational speed of turret, maximum number of dies, and maximum production capacity, this machine is an ideal choice for high-volume pharmaceutical production lines. Its use of GCr15 for the material of the die and its flexible power options further enhance its durability and adaptability, making it a reliable addition to any pharmaceutical production facility.

Technical Parameters:

| Detailed Product Description | |||

|---|---|---|---|

| Model: | ZP-29D Tablet Press Machine | ||

| Max Pressure: | 100KN | ||

| Size of Machine: | 1040×910×1690mm | ||

| Max Diameter of Tablet: | 25mm | ||

| Material of Die: | GCr15 | ||

| Weight of Machine: | 1600kg | ||

| Max Depth of Filling: | 24mm | ||

| Max Thickness of Tablet: | 12mm | ||

| Max Number of Dies: | Max 29 Sets | ||

| Power: | 220/380V | ||

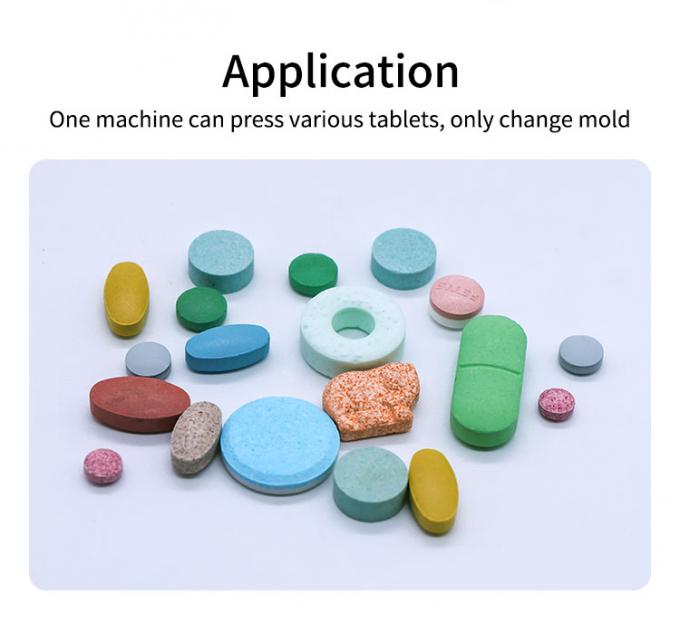

Applications:

The Rich Packing ZP-29D rotary tablet press is ideal for use in different product application occasions and scenarios. This machine is suitable for both small and large-scale manufacturing operations. It can be used to manufacture tablets for various purposes such as medicines, dietary supplements, and confectionery. This rotary tablet press can produce tablets with a maximum diameter of 25mm, a max depth of filling of 24mm, and a maximum production capacity of 110,000pcs/h. Moreover, it can accommodate up to 29 sets of dies, making it highly efficient and reliable.

The Rich Packing ZP-29D rotary tablet press is easy to use, maintain, and clean. It has a compact design with a size of 1040×910×1690mm, making it easy to install in any manufacturing facility. It is also designed to ensure the safety of the operator and the product by preventing contamination and minimizing downtime. The equipment is wrapped in a film moisture-proof treatment, and the standard export wooden box is reinforced to ensure the safety of the tablet press during transportation. The machine can be operated using different payment methods such as L/C, T/T, Western Union, D/A, D/P, T/T, Western Union, MoneyGram. The minimum order quantity for this product is one machine, and the delivery time is 5-10 working days. The supply ability of this product is 45 pcs/month, ensuring that customers can order the product anytime they need it.

Support and Services:

The Tablet Press Machine product technical support and services include:

– Troubleshooting and problem-solving assistance

– Product installation and setup guidance

– User training and education

– Maintenance and repair services

– Replacement parts and accessories

– Technical documentation and user manuals

– Software updates and upgrades

– Product customization and configuration

– Quality control and assurance services

Packing and Shipping:

Product Packaging:

- The tablet press machine will be packed securely in a wooden crate to prevent any damages during shipping.

- All necessary parts and accessories will be included in the package.

- The package will be labeled with product information and handling instructions.

Shipping:

- The tablet press machine will be shipped via a reputable courier service.

- Customers will receive a tracking number once the package has been shipped.

- Shipping times may vary depending on the customer's location.

- Customers are responsible for any customs or import duties that may apply.

- In the event of any issues with shipping or delivery, please contact our customer service team for assistance.