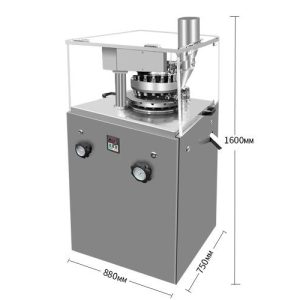

Double Layers Automatic Tablet Press Machine For Pharmaceutical Enterprises

Detailed Product DescriptionName:Double Layers Automatic Rotary Tablet Press Machine For Pill TabletDies No.:27 SetMax. Production Capacity:90000 Pcs/hMax.?Pressure:100KNMax.?Dia. Of?Tablet:25mmMax.?Thickness Of Tablet:8mmDia. Of Middle Die:??38.1mmDia.of Upper/Lower Punching Bar:??25.4mmMax. Depth Of…

- Estimated Delivery : 7 Days Fast Delivery

- Certification : cGMP CE ISO SGS and etc

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| Name: | Double Layers Automatic Rotary Tablet Press Machine For Pill Tablet | ||

| Dies No.: | 27 Set | ||

| Max. Production Capacity: | 90000 Pcs/h | ||

| Max.?Pressure: | 100KN | ||

| Max.?Dia. Of?Tablet: | 25mm | ||

| Max.?Thickness Of Tablet: | 8mm | ||

| Dia. Of Middle Die: | ??38.1mm | ||

| Dia.of Upper/Lower Punching Bar: | ??25.4mm | ||

| Max. Depth Of Filling: | 17mm | ||

| Rotary Speed: | 5??28 R/min | ||

| Length Of Upper/Lower Punching Bar: | 133.4mm | ||

| Motor: | 5.5kw | ||

| Weight Of Machine: | 1800kg | ||

| Outline Dim.: | 1100??940??1755mm | ||

| Packing Size: | 1520??1100??2130mm | ||

| Packing Size Of Dust Collector: | 960??620??1460 Mm | ||

| Highlight: |

pill press machine, tablet pill press machine |

||

Double Layers Automatic Rotary Tablet Press Machine for Pill Tablet

Introduction of tablet press machine

The tablet compress machine is the preferred product in pharmaceutical, chemical, electronics, food and other enterprises in production, the pharmacy pill press machine is also suitable for pressing that material that is difficult formed into tablet, meet the requirements of GMP production.

Features of automatic pharmacy tablet press machine:

1.Good sealing performance, the pharmacy tablet press machine can prevent cross pollution.

2.High pressure, this pharmaceutical tablet press machine adapts "Down pressure guide", the pressure is big, can suppress the hard material.

3.The tablet press machine equips high equipment configuration. The core components are all famous brand products such as German SIEMENS and Japanese OMRON, with long service life and low failure rate.

4.High efficiency and high cost performance. This tablet press machinery adopts single pressure, IPT die, the maximum pressure is 80 kN, maximum press diameter 25mm, maximum capacity 40000/ hours, maximum press thickness 8mm.

5.The tablet press machinery meets the requirements of GMP. The whole shell is made of stainless steel, and the chamber is separated from the outside environment by the organic glass, with good sealing. All the contacting parts of the tablet press meet the requirements of "no poison, no odor and corrosion prevention". The turntable is made of nodular cast iron and strictly implemented for 12 months, which is hard, wearable, non-toxic and smooth, which fully meets the requirements of GMP.

| Detailed Product Description | |||

|---|---|---|---|

| Dies No. | 27 set | ||

| Max. Production Capacity | 90000 pcs/h | ||

| Max. Pressure | 100KN | ||

| Max. Dia. of Tablet | 25mm | ||

| Max. Depth of Filling | 17mm | ||

| Max. Thickness of Tablet | 8mm | ||

| Dia. Of Middle Die | ??38.1mm | ||

| Length of Upper/Lower Punching Bar | 133.4mm | ||

| Dia.of Upper/Lower Punching Bar | ??25.4mm | ||

| Rotary Speed | 5??28 r/min | ||

| Motor | 5.5kw | ||

| Weight of Machine | 1800kg | ||

| Outline Dim. | 1100×940×1755mm | ||

| Packing Size | 1520×1100×2130mm | ||

| Packing size of Dust Collector | 960×620×1460 mm | ||

Turntable: The turntable is made of ductile iron and is aged strictly for 12 months. It is hard, wear-resistant, non-toxic and smooth, and fully meets the requirements of GMP.