automatic double layers rotary tablet pharmaceutical pill press machine

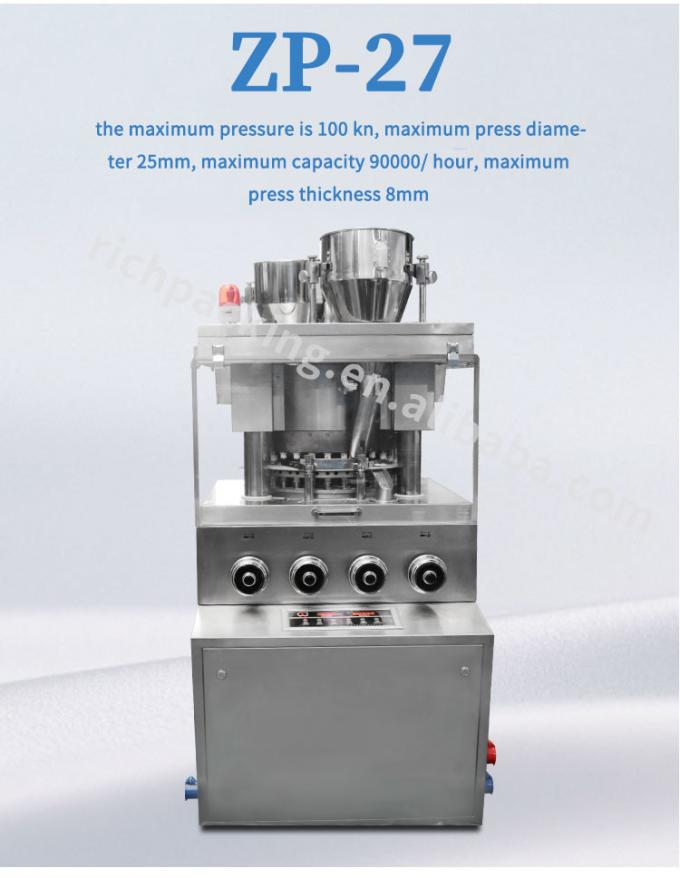

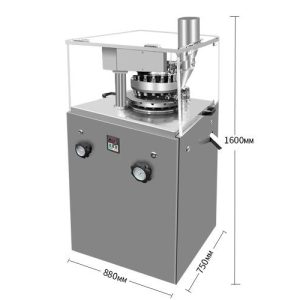

Detailed Product DescriptionAfter-sales Service Provided:Engineers Available To Service Machinery OverseasMax. Production Capacity:90000 Pcs/hMax.?Pressure:100KNMax.?Dia. Of?Tablet:25mmMax. Depth Of Filling:17mmMax.?Thickness Of Tablet:8mmDia. Of Middle Die:??38.1mmWarranty:1 YearRotary Speed:5-28 R/…

- Estimated Delivery : 7 Days Fast Delivery

- Certification : cGMP CE ISO SGS and etc

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | ||

| Max. Production Capacity: | 90000 Pcs/h | ||

| Max.?Pressure: | 100KN | ||

| Max.?Dia. Of?Tablet: | 25mm | ||

| Max. Depth Of Filling: | 17mm | ||

| Max.?Thickness Of Tablet: | 8mm | ||

| Dia. Of Middle Die: | ??38.1mm | ||

| Warranty: | 1 Year | ||

| Rotary Speed: | 5-28 R/min | ||

| Weight Of Machine: | 1800kg | ||

| Outline Dim.: | 1100??940??1755mm | ||

| Highlight: |

pill press machine, tablet pill press machine |

||

automatic double layers rotary tablet pharmaceutical pill press machine

| Detailed Product Description | |||

|---|---|---|---|

| Dies No. | 27 set | ||

| Max. Production Capacity | 90000 pcs/h | ||

| Max. Pressure | 100KN | ||

| Max. Dia. of Tablet | 25mm | ||

| Max. Depth of Filling | 17mm | ||

| Max. Thickness of Tablet | 8mm | ||

| Dia. Of Middle Die | ??38.1mm | ||

| Length of Upper/Lower Punching Bar | 133.4mm | ||

| Dia.of Upper/Lower Punching Bar | ??25.4mm | ||

| Rotary Speed | 5??28 r/min | ||

| Motor | 5.5kw | ||

| Weight of Machine | 1800kg | ||

| Outline Dim. | 1100×940×1755mm | ||

| Packing Size | 1520×1100×2130mm | ||

| Packing size of Dust Collector | 960×620×1460 mm | ||

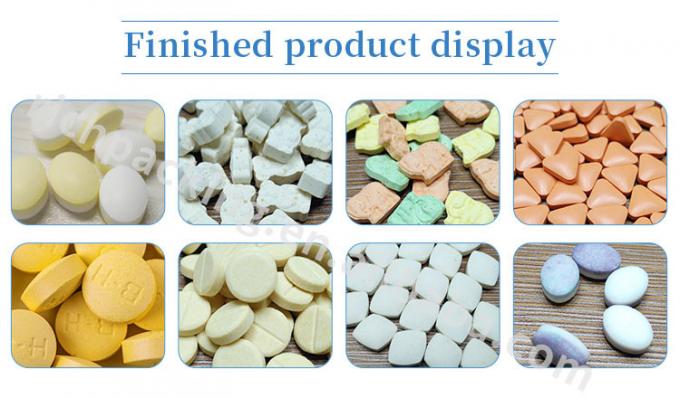

Latest tablet compress machine pharmacy pill making compress machine manufacture

1,High efficiency and high cost performance. This machine adopts double pressure, the maximum pressure is 100 kN, maximum press diameter 25mm, maximum capacity 90000/ hours, maximum press thickness 8mm.

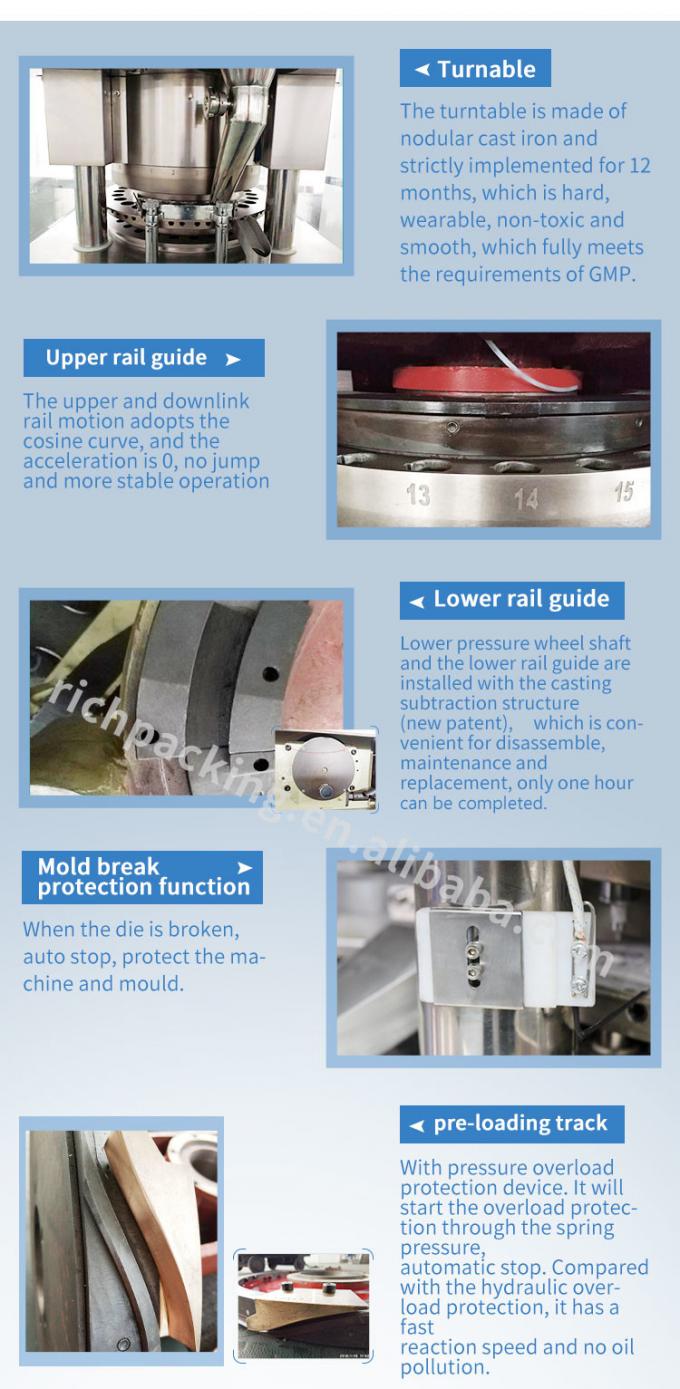

2,It meets the requirements of GMP. The whole shell is made of stainless steel, and the chamber is separated from the outside environment by the organic glass, with good sealing. All the contacting parts of the tablet press meet the requirements of "no poison, no odor and corrosion prevention". The turntable is made of nodular cast iron and strictly implemented for 12 months, which is hard, wearable, non-toxic and smooth, which fully meets the requirements of GMP.

3,The equipment has high precision, stable weight, sensitive adjustment and smooth operation.

3.1 The hole of upper punch, lower punch and middle mold, the axis of outer circle to the center of the shaft hole coaxiality is H8 (-0.165/0).

3.2 The contact parts of die hole surface and the upper and lower die and rail roughness Ra≤1.6μm, the feeder is tin bronze (ZQSn6-6-3) material, the surface of nickel chromium, the bottom roughness Ra≤0.8μm.

3.3 The sensitivity of the hand wheel is 0.1mm.

3.4 The upper and downlink rail motion adopts the cosine curve, and the acceleration is 0, no jump and more stable operation.

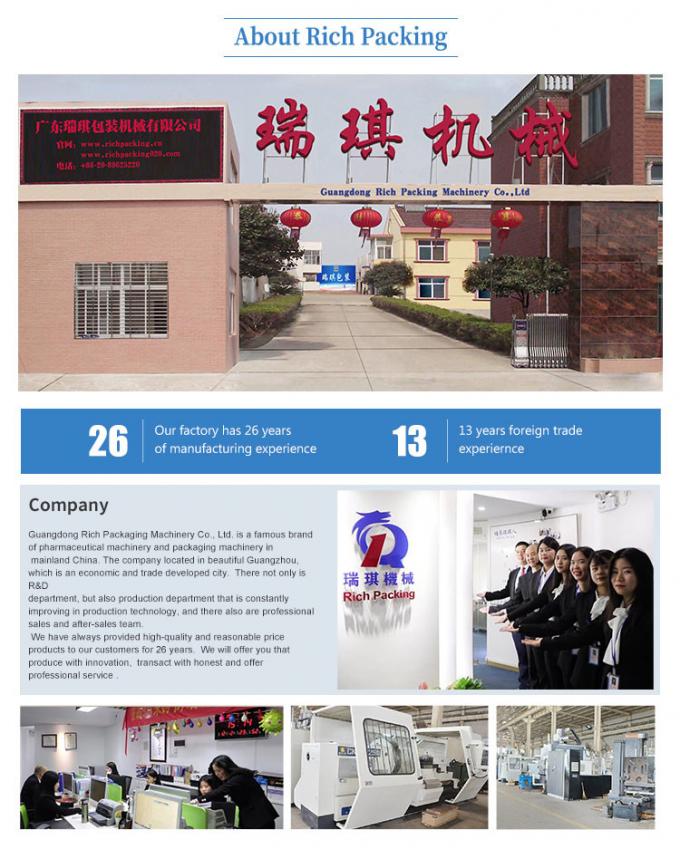

Guangdong Rich Packaging Machinery Co., Ltd. is a famous brand of pharmaceutical machinery and packaging machinery in mainland China. The company located in beautiful Guangzhou, which is an economic and trade developed city. There not only is R&D department, but also production department that is constantly improving in production technology, and there also are professional sales and after-sales team.

We have always provided high-quality and reasonable price products to our customers for 25 years. We will offer you that produce with innovation, transact with honest and offer professional service .

Our products have sale to more than 65 countries, such as the United States, Canada, Thailand, Australia. By the way, our products and service are recognized as we share Integrity, responsibility, kindness, hard work and profession to our buyers.

We always believe that Rich Packing will become better and look forward to cooperation with you in future.