High Speed Vision Counting Bottling Machine for Tablet Capsule with CCD System

Подробная система описания продукта:Vision Inspection SystemProduct Name:Visual Counting Bottling MachineCounting Rate:100%Материал:SUS-316L Stainless SteelControl System:PLCPower Supply:AC110/220/380V 50/60HZCOUNTING SPEED:Максимум 252,000 Pcs/minCapacity:35-70 Bottles/min*, *::before, *::after…

- Расчетная доставка : 7 Дни быстрая доставка

- Сертификация : CGMP CE ISO SGS и т. Д.

- Послепродажи предоставлены : Инженеры доступны для обслуживания машины за рубежом.

| Подробное описание продукта | |||

|---|---|---|---|

| Операционная система: | Vision Inspection System | ||

| Название продукта: | Visual Counting Bottling Machine | ||

| Ссылка: | 100% | ||

| Материал: | SUS-316L из нержавеющей стали | ||

| Система управления: | ПЛК | ||

| Источник питания: | AC110/220/380V 50/60 Гц | ||

| Скорость подсчета: | Максимум 252,000 ПК/мин | ||

| Емкость: | 35-70 Бутылки/мин | ||

Описание продукта:

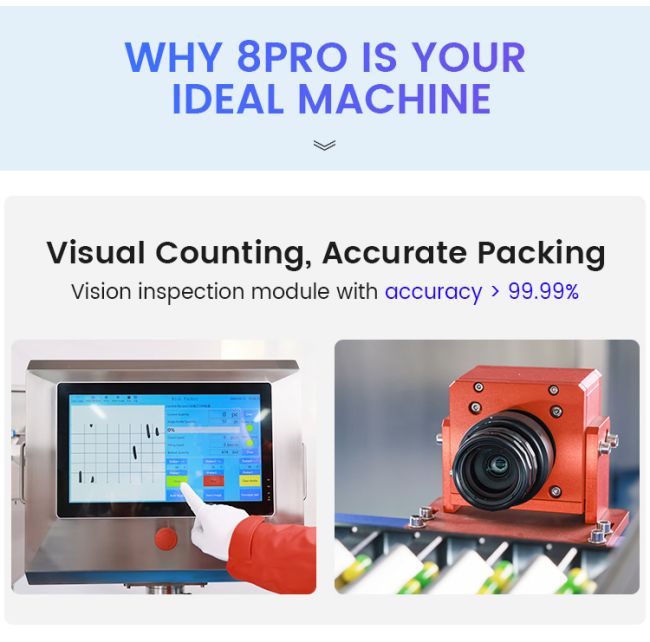

The Automatic Counting Machine, an exemplary innovation in pharmaceutical and packaging automation, stands as a testament to the evolution of precision and efficiency in the capsule and tablet counting industry. Engineered to cater to the incessant demand for accuracy and reliability, this machine incorporates a state-of-the-art Vision Inspection System as its core operational system. This cutting-edge technology ensures each capsule or tablet is counted and inspected with the utmost precision, minimizing the risk of errors that are often associated with manual counting methods.

At the heart of the Automatic Counting Machine lies its robust and dependable Control System—a Programmable Logic Controller (ПЛК) that orchestrates the machine’s operations seamlessly. The PLC facilitates a user-friendly interface and allows for an automated process that is both flexible and precise. It is the pivotal component that integrates all machine functions, ensuring a consistent and error-free output that is crucial in pharmaceutical manufacturing and packaging processes.

The machine boasts a remarkable capacity, efficiently handling 35-70 Bottles per minute, which speaks volumes about its capability to keep up with high-demand production schedules. The throughput of the Automatic Counting Machine makes it an invaluable asset for businesses looking to scale their operations without compromising on the quality or accuracy of their products. Whether it’s a small-scale setup or a large-scale production line, this machine’s capacity ensures that output demands are met with unmatched efficiency.

One of the pivotal aspects of the Automatic Counting Machine is its power supply versatility. Designed to accommodate a wide range of industrial power standards, the machine can operate on AC110/220/380V at a frequency of 50/60Hz. This feature ensures that the machine can be deployed in various geographic locations without the need for complex power conversion solutions, thus simplifying installation and operation processes for end-users around the globe.

When it comes to construction, the Automatic Counting Machine does not compromise on quality. It is built with SUS-316L Stainless Steel, a premium-grade material known for its superior strength, durability, and resistance to corrosion. This choice of material is particularly important in the pharmaceutical sector, where maintaining the highest standards of cleanliness and hygiene is paramount. The stainless steel construction ensures that the machine can withstand rigorous cleaning protocols and maintain its integrity over countless operation cycles.

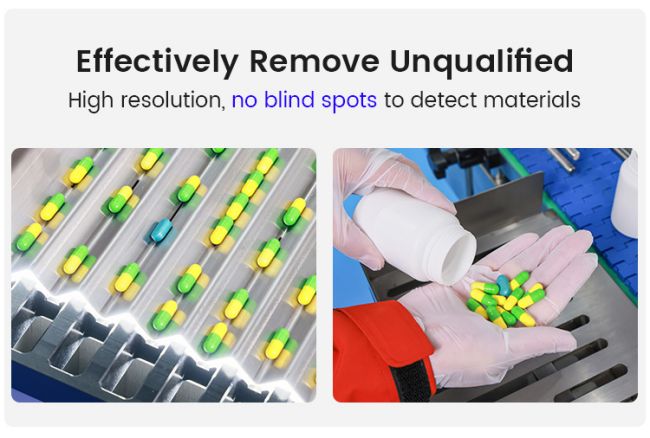

As a capsule counting machine, it stands out as a specialized solution for handling delicate pharmaceutical products. The precision-engineered components and vision inspection system work in tandem to accurately count capsules, ensuring that each bottle contains the correct dosage. This level of accuracy is crucial for maintaining patient safety and adhering to stringent regulatory standards.

Furthermore, the automatic vision capsule tablet counter feature of the machine brings automation to new heights. This functionality eliminates the need for manual counting, thereby reducing labor costs and the potential for human error. The vision counting machine component is specially designed to detect and count tablets with a high degree of accuracy, ensuring that each packaged product meets the exact specifications required by health authorities and customers.

In conclusion, the Automatic Counting Machine is the epitome of modern automated counting solutions, combining a vision inspection system, PLC control, versatile power supply options, and robust construction into one sophisticated machine. It is the perfect solution for pharmaceutical companies seeking to enhance their production efficiency, accuracy, and product integrity. This machine is not just a piece of equipment; it is an investment in quality and excellence that will deliver returns for many years to come.

Технические параметры:

| Подробное описание продукта | |||

|---|---|---|---|

| Parameter | Спецификация | ||

| Название продукта | Visual Counting Bottling Machine | ||

| Источник питания | AC110/220/380V 50/60 Гц | ||

| Емкость | 35-70 Бутылки/мин | ||

| Материал | SUS-316L из нержавеющей стали | ||

| Система управления | ПЛК | ||

| Ссылка | 100% | ||

| Скорость подсчета | Максимум 252,000 ПК/мин | ||

| Операционная система | Vision Inspection System | ||

| Подробное описание продукта | |||

|---|---|---|---|

|

How to Contact Us? |

|||

|

Электронная почта |

Manager@richpacking.cn | ||

|

WhatsApp & WeChat |

+86-138-2609-3596 | ||

|

Visit WebSite |

www.richpacking020.com | ||