NJP Series Electronic Fully Automatic Rotary Capsule Filling Machine

Detailed Product DescriptionAfter-sales Service:Инженеры доступны для обслуживания машины за рубежом,Video Technical Support,Online SupportOutput Capacity:88800 Капсулы/часСостояние:New ProductType Of Model:Auto Capsule Filling MachineWorking Voltage:220-380V 50HzDriven Type:Electric TypePower Supply…

- Расчетная доставка : 7 Дни быстрая доставка

- Сертификация : CGMP CE ISO SGS и т. Д.

- Послепродажи предоставлены : Инженеры доступны для обслуживания машины за рубежом.

| Подробное описание продукта | |||

|---|---|---|---|

| Послепродажная служба: | Инженеры доступны для обслуживания машины за рубежом,Video Technical Support,Онлайн -поддержка | ||

| Output Capacity: | 88800 Капсулы/час | ||

| Состояние: | New Product | ||

| Type Of Model: | Автоматическая наполнительная машина | ||

| Working Voltage: | 220-380V 50 Гц | ||

| Приводящий тип: | Электрический тип | ||

| Power Supply W: | 10450 | ||

| Автоматический класс: | Fullly Automatic | ||

| Гарантия: | 2 Год | ||

| Name Of Machine: | Rotary Capsule Filling Machine | ||

| Выделять: |

Rotary Capsule Filling Machine, Автоматическая наполнительная машина |

||

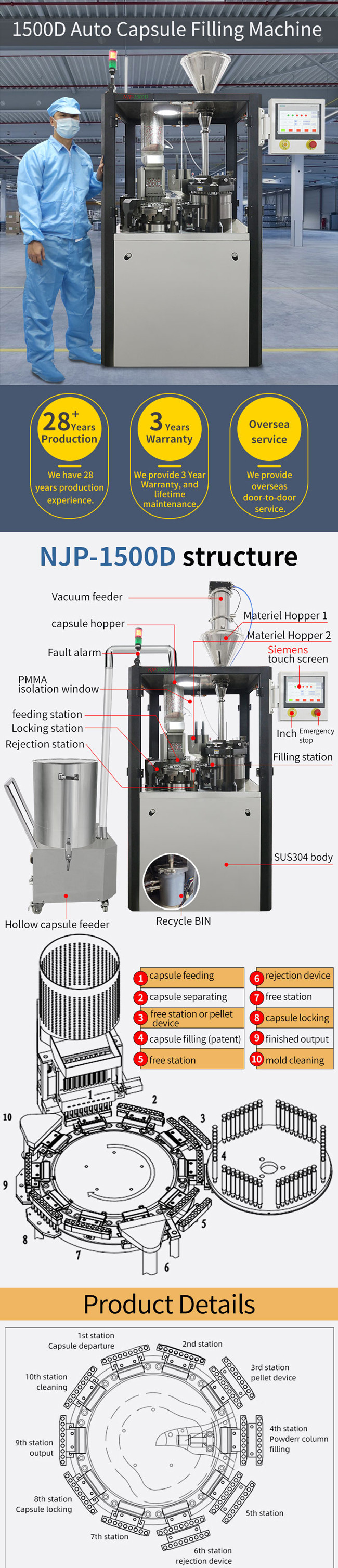

NJP Series Electronic Fully Automatic Rotary Capsule Filling Machine

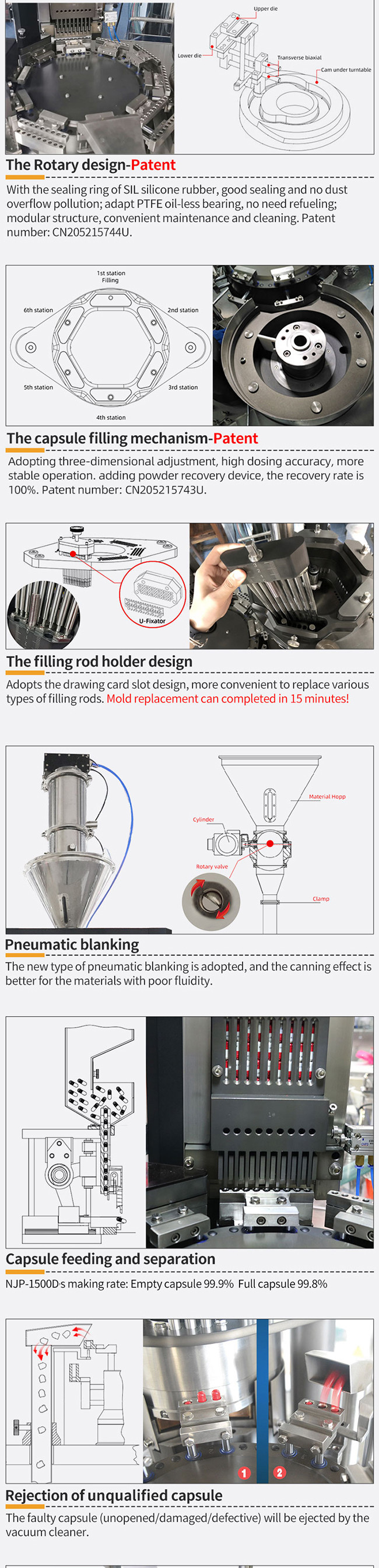

1500D capsule filling machine: The 1500D capsule filling machine of our Rich Packing company using the turntable type filling structure, according to the patent design. This 1500D model has ten working positions. When the 1500D model start running, its turntable rotate runs counterclockwise. А 1 и 2 working station are the capsule separate position, the 3 or 4 working station is the grainule feeding position, the 4 working station is the feeding powder position, the 6 working station is rejection function, the 7 и 8 working station are to lock the capsules, the 9 working station is finished product output working station, and the 10 working station is to clean rods before start working.

The powder filling working position: When the rotary and ten working positions operate, the complete working process of filling capsules is completed. The very important of the ten positions is the fourth working station, the powder filling working position. According to the feedback from our customers that it would take a very long time to replace the mold and the current situation of the filling capsule industry, we have improved the filling rod, so that the filling mold can be replaced in 15 мин.

Rejection function: The function of the sixth working position is rejection. When in the process of filling the capsules, the capsules that separated uncorrectly, the capsule shell damaged, or the filling dose insufficient. When the turntable is turned to the rejection position, the high-pressure adsorption station will suck away the waste. The capsule shell and the material would be separated,to avoid the powder pollution, and the discarded shell is collected by the same time.

| Подробное описание продукта | |||

|---|---|---|---|

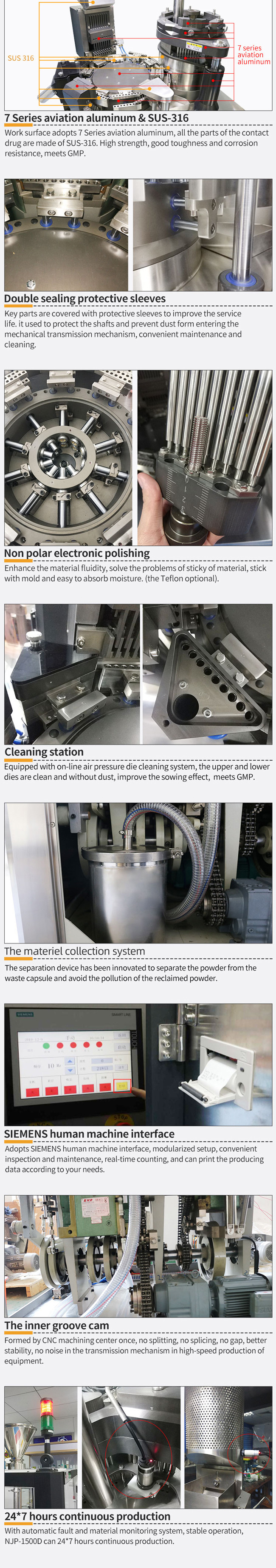

| Product of max capacity | 90000 ПК/ч | ||

| weight of 1500d model | 1,200Кг | ||

| Общий размер машины | 900*870*1950мм | ||

| Power Vol. | 360/220V 50 Гц | ||

| power of supply | 5480W. | ||

| No.of segment hole | 9 | ||

| Vacuum pressure | 38.5M3/H.-0.04-0.079МПА | ||

capsule filling machine machine capsule filling capsule filling

automatic machine capsule filling