Automatic Capsule Filling Machine Gmp Certified Capsule Filling Machinery For Pharmaceutics Powder

Подробное описание продукта предоставляется услуги.:Online SupportCondition:Ньютип:Filling MachineApplication:Medical,FoodVoltage:220V/380VAutomatic Grade:AutomaticWarranty:1 YearUsage:Capsule FillingFeature:High-precisionHighlight:Автоматический капсульный наполнитель, auto capsule filling machineNJP-1500…

- Расчетная доставка : 7 Дни быстрая доставка

- Сертификация : CGMP CE ISO SGS и т. Д.

- Послепродажи предоставлены : Инженеры доступны для обслуживания машины за рубежом.

| Подробное описание продукта | |||

|---|---|---|---|

| Послепродажная служба предоставлена: | Онлайн -поддержка | ||

| Состояние: | Новый | ||

| Тип: | Filling Machine | ||

| Приложение: | Medical,Еда | ||

| Напряжение: | 220V/380V | ||

| Автоматический класс: | Автоматический | ||

| Гарантия: | 1 Год | ||

| Usage: | Capsule Filling | ||

| Особенность: | High-precision | ||

| Выделять: |

Автоматический капсульный наполнитель, Автоматическая наполнительная машина |

||

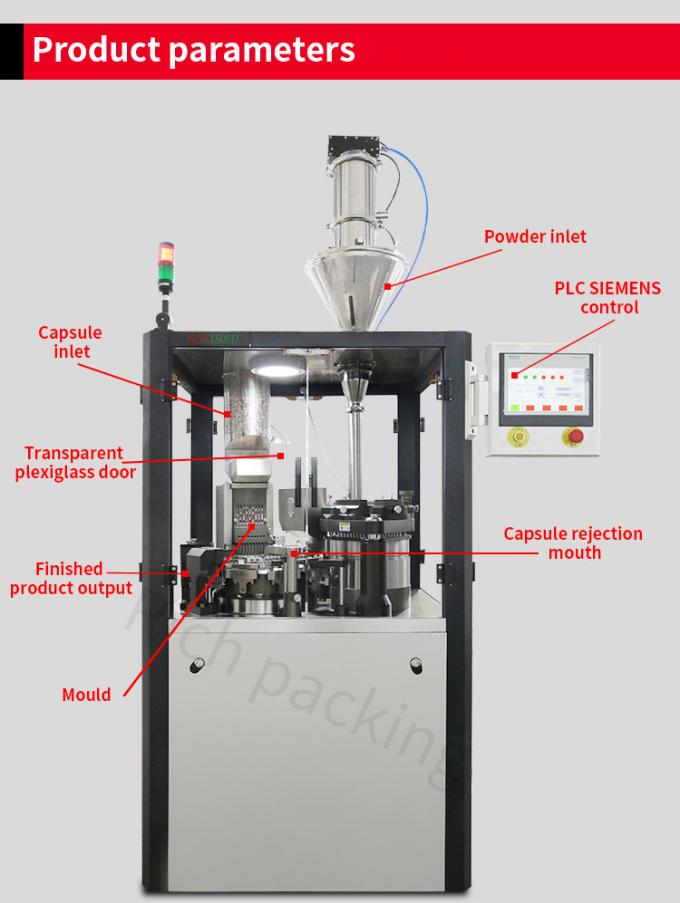

NJP-1500D this model capsule filling machine is the latest D-type innovative product developed by the company. It has 7 major technological innovations and 2 invention patents.,It can fill powder, гранулы и другие материалы в полые капсулы (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#). It can automatically finish the production process including sowing, capsule separating, наполнение, блокировка, unqualified capsule rejected and finished products output. It has the advantages of accurate loading, stable operation and no dust. It meets the GMP и JB20025-2004

| Подробное описание продукта | |||

|---|---|---|---|

| Производственные мощности | 90000 ПК/ч | ||

| Чистый вес машины | 1200Кг | ||

| Общий размер машины | 900×870×1950мм | ||

| Власть | 380/220V 50 Гц | ||

| Общая мощность | 5.5КВт | ||

| Нет. Сегментных отверстий | 9 | ||

| Вакуум | 40M3/H.-0.04-0.08МПА | ||

| Пылевой коллектор | 24.5Kpa 210m3/час | ||

| Шум | <75ДБ(А) | ||

| Создание скорости | Пустая капсула 99.9% Полная капсула 99.8% | ||

| Применимая капсула | 00,0,1,2,3,4,5# | ||

| Ошибка заполнения | Западная медицина:±3% Китайская медицина:±4% | ||

| Применимый продукт | Власть,гранула,гранул,планшет | ||

| Размер упаковки | 1490×1260×2150мм | ||

1, Reasonable design,the working stations adopt design mode with low platform, модульная структура, Легкая работа и более низкая частота отказов.

2, Safety first, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

3, Segmentation adapt German Cai Si for 3 секунды (Zeiss) Оптическая разделительная индексация головы, Индексация вала завершила единовременную обработку, нагрузка и высокая точность, ошибка меньше или равна 3%.

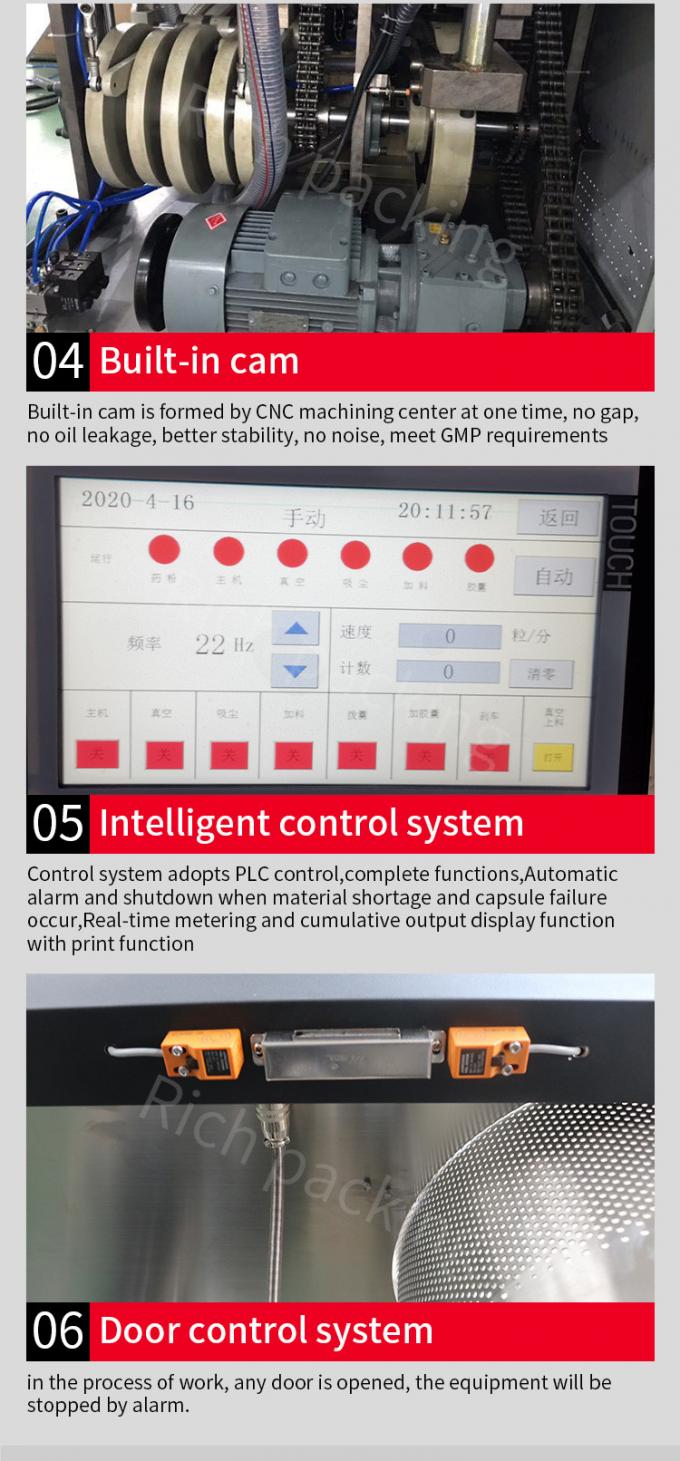

4, Machine maintenance is very easy, just need lubricate the cam one timein the capsule filling machine then the grease can be continuously lubricated, ensuring smooth transmission of the transmission mechanism.and no oil leaking,conform to the GMP requirements

5, Rotary design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow pollution; Transverse biaxial adapt PTFE oil-less bearing, no need refueling; модульная структура, equipped with jog operation, convenient maintenance and cleaning, replacement of mold only 15 minutes.

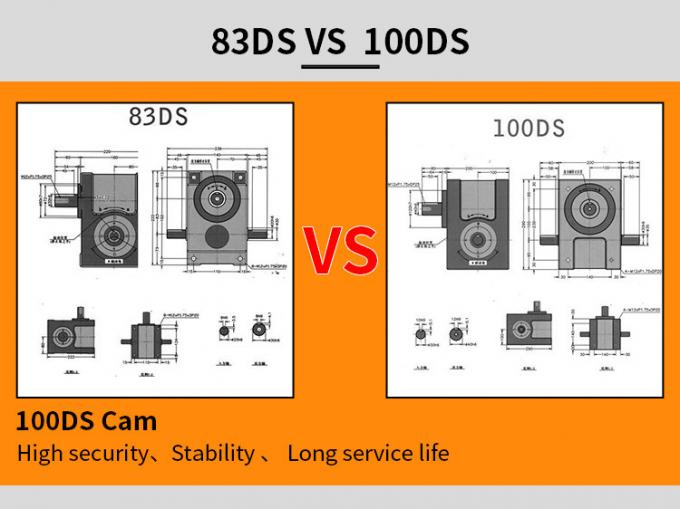

5, NJP-1500D capsule filling machine adopts large high precision cam indexing box, completely changed the past 83DS failure frequency, even the phenomenon of the fracture of the force shaft and the output shaft. It is the only enterprise that adopts 100DS and 100DS indexing box in our country at present. The continuous operation of the equipment has been guaranteed.

6, The inner groove cam of NJP-1500D capsule filling machine is formed by CNC machining center once, no splitting, no splicing, no gap, better stability, no noise in the transmission mechanism in high-speed production of equipment.

7, The filling mechanism obtains the national new patent, adopts the three-dimensional adjustment, makes the metering plate evenly force, the adjustment volume is precise and quick, and the powder recovery device is added, the recycling rate is 100%, which reduces the waste and improves the economic benefit.

8, Capsule suction, capsule outlet, locking and waste rejection adapt double sealing device, one is imported NBR sealing rubber which prevents the loss of lubricating oil. The other seals use the imported SIL silicone rubber sealing ring to block the powder into the bearing, which effectively solves the problem of the card machine that the powder enters the bearing.

9, The capsule filling machine filling rod holder adopts the drawing card slot design, and it is more convenient to replace various types of filling rods.

10, Equipped with on-line air pressure die cleaning system, the upper and lower dies are clean and without dust, improve the sowing effect.

11, Precision mold concentricity, zero deviation, ensure that the capsule is not wiping, no damage..

12,The filling rod, the upper and lower die holes, the measuring disk adapt non polar electronic polishing treatment, enhance the material fluidity, which has solved the problems of sticky of material, stick with mold and easy to absorb moisture. (According to the material properties and the special requirements of customers, we can provide the Teflon coating processing service)

13, The separation device has been innovated to separate the powder from the waste capsule and avoid the pollution of the reclaimed powder. (Optional)

14, The control appliance adopts the world famous brand, modularized setup, convenient inspection and maintenance, SIEMENS human machine interface, real-time counting, and can print the equipment according to customer needs, print production date, batch number, code, и т. д..

15, All the parts of the contact drug are made of stainless steel 316, и устройство отходов принимает семь линий аэродинамического алюминия.

16, The equipment is high production, низкое потребление энергии, удобно в очистке и стабильной в эксплуатации. It is suitable for continuous production of 24 часы.