5.5kw Amoxicillin Pill Making Machine With Auto Protective Function

Подробное описание продукта:Auto Protective Function Traditional Honey Pill Making Machine / Amoxicillin Tablet Pressing MachineMax.?Давление:100KNMax. Производственные мощности:90000 Pcs/hMax.?Является. Of?Планшет:25mmMax.?Thickness Of Tablet:8mmMotor:5.5kwRotary Speed:5??28 R/minPacking Size:1520??1100??213…

- Расчетная доставка : 7 Дни быстрая доставка

- Сертификация : CGMP CE ISO SGS и т. Д.

- Послепродажи предоставлены : Инженеры доступны для обслуживания машины за рубежом.

| Подробное описание продукта | |||

|---|---|---|---|

| Имя: | Auto Protective Function Traditional Honey Pill Making Machine / Amoxicillin Tablet Pressing Machine | ||

| Max.?Давление: | 100KN | ||

| Максимум. Производственные мощности: | 90000 ПК/ч | ||

| Max.?Является. Of?Планшет: | 25мм | ||

| Max.?Thickness Of Tablet: | 8мм | ||

| Мотор: | 5.5кВт | ||

| Скорость вращения: | 5??28 R/мин | ||

| Размер упаковки: | 1520??1100??2130мм | ||

| Выделять: |

pill press machine, capsule press machine |

||

5.5kw Amoxicillin Pill Making Machine With Auto Protective Function

Introduction of tablet press machine

High efficiency and high cost performance.ZP-27 is an automatic rotary tablet press. It is suitable for continuous pressing of powder and particles into wafers, special-shaped sheets, dichroic and annular sheets. It is the preferred product of pharmaceutical, chemical, electronic, food and other manufacturers. It is also suitable for pressing tablets which are difficult to form, and meets the requirements of GMP production.

Features of automatic pharmacy tablet press machine:

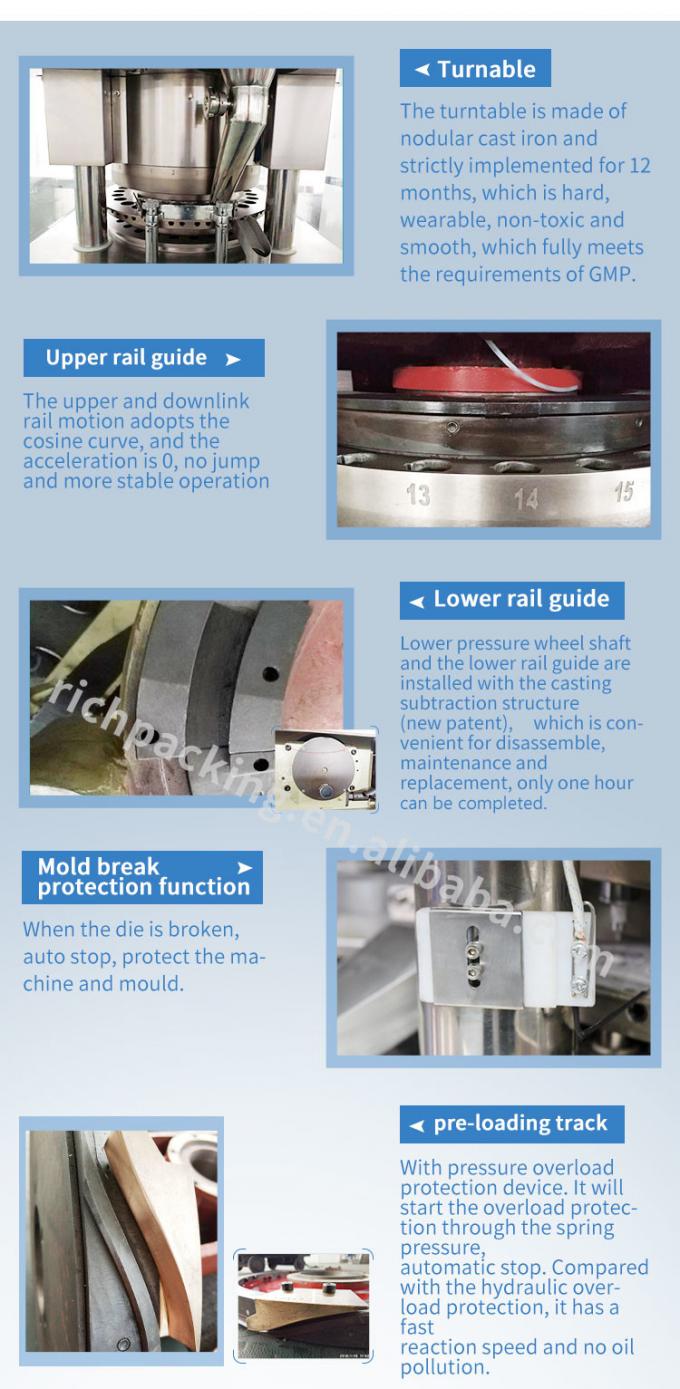

1.The hole of upper punch of tablet press machine, lower punch and middle mold, the axis of outer circle to the center of the shaft hole coaxiality is H8 (-0.165/0).

2.The contact parts of tablet press machinery die hole surface and the upper and lower die and rail roughness Ra≤1.6μm, the feeder is tin bronze (ZQSn6-6-3) материал, the surface of nickel chromium, the bottom roughness Ra≤0.8μm.

3.The principle of pill compress machine eccentric torque is used to protect the die and machine. Compared with the hydraulic overload protection, it has a fast reaction speed and no oil pollution

4.The tablet press machine has intelligent lubrication system. The technology of BIJUR DELIMON, USA, is used to provided timely, quantitative and timely refueling for parts that need lubrication. The quantity of oil can be flexibly adjusted according to the specific environment of customers.

5.High pressure, this pharmaceutical tablet press machine adapts "Down pressure guide", the pressure is big, can suppress the hard material.

| Подробное описание продукта | |||

|---|---|---|---|

| Dies No. | 27 set | ||

| Максимум. Производственные мощности | 90000 ПК/ч | ||

| Максимум. Давление | 100KN | ||

| Максимум. Является. of Tablet | 25мм | ||

| Максимум. Depth of Filling | 17мм | ||

| Максимум. Thickness of Tablet | 8мм | ||

| Является. Среднего кубика | ??38.1мм | ||

| Length of Upper/Lower Punching Bar | 133.4мм | ||

| Диа. о верхней/нижней панели | ??25.4мм | ||

| Скорость вращения | 5??28 r/min | ||

| Мотор | 5.5кВт | ||

| Weight of Machine | 1800кг | ||

| Outline Dim. | 1100×940×1755мм | ||

| Размер упаковки | 1520×1100×2130мм | ||

| Packing size of Dust Collector | 960×620×1460 мм | ||