220/380V Fully Automatic Cartoning Machine 35-125 Carton / Min Speed

Szczegółowa nazwa opisu produktu:Fully Automatic Carton Box Cartoning Food Bottle Blister Pharmaceutical MachineSpeed:35-125 Moc kartonowa/miętotyczna:1.10 Kwsize zakres kartonu:L(65-150)*W(35-85)*H(12-45)mmRange Of Folding Times Of Instructions:1-4 FoldPower Supply:220/380V 50HzCarton Weight:240-360…

- Szacowana dostawa : 7 Dni szybka dostawa

- Orzecznictwo : CGMP CE ISO SGS i itp.

- Dostarczone posprzedażne : Inżynierowie dostępni do serwisowych maszyn za granicą.

| Szczegółowy opis produktu | |||

|---|---|---|---|

| Nazwa: | Fully Automatic Carton Box Cartoning Food Bottle Blister Pharmaceutical Machine | ||

| Prędkość: | 35-125 Karton/min | ||

| Całkowita moc: | 1.10 KW | ||

| Zakres wielkości kartonu: | L(65-150)*W(35-85)*H(12-45)mm | ||

| Range Of Folding Times Of Instructions: | 1-4 Fold | ||

| Zasilacz: | 220/380V 50Hz | ||

| Waga kartonu: | 240-360G/?O | ||

| Zakres wielkości instrukcji: | L(78-250)*W(85-170)mm | ||

| Waga instrukcji: | 60-70G/?O | ||

| Pressure Intensity: | ??0.6MPA | ||

| Zużycie powietrza: | 120-160 L/min | ||

| Ogólny rozmiar maszyny: | 2150*1140*1800?L | ||

| Waga netto maszyny: | 1500kg | ||

| Atrakcja: |

carton packing machine, cartonator packing machine |

||

Fully Automatic Carton Box Cartoning Food Bottle Blister Pharmaceutical Machine

Wprowadzenie maszyny do kartonowania:

Automatic vertical cartoning packing machine can packed various products such as aluminum plastic plate and aluminum aluminum plate, electronic cigarette,Cleanser na twarzy,ointment,Sealed pouch various bottled products.The automatic cartoning packing machine manufactured by Guangdong Rich Packing Machinery Co.,Ltd has strong compatibility and can pack products of various specifications on one machine.

his automatic vertical cartoning machine is the preferred products for small and medium sized production in pharmaceutical manufacturing,chemical industry, electronic products and food industry, it meets the requirements of GMP.

Funkcje pakowania pudełka z kartonowaniem:

1. All the materials of cartonging machine are made of stainless steel or nickel-chromium plated material, with stable chemical performance, corrosion resistance, non-toxicity and harmlessness. The welding position of cartoning machine is

tempered and durable.

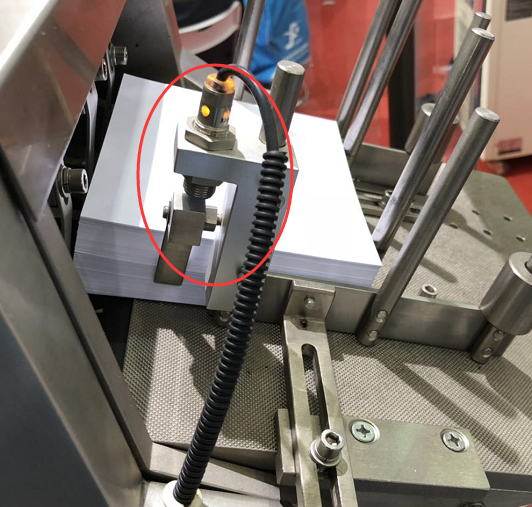

2. The cartoning box packing machine with high intelligence,accurate loading monitoring.Detection points are densely distributed in various workplaces, such as feeding, quantity detection , packaging into conveyer belt, number of

packages, carton in place and so on. The whole process of inspection and result detection is monitored through the process.

3. The automatic vertical cartoning packing machine produced by Guangdong Rich Packing Machinery Co.,Ltd has stable performance and is suitable for 24 hours operation.

4. The automatic cartoning box packing mchines equip spare part are engraved with codes,convenient customer to daily maintenance and repair.

5. This cartoning packing machine covers an area of about 3?O and is easy to handle and use.

| Szczegółowy opis produktu | |||

|---|---|---|---|

| Model | RQ-ZHL-12OL | ||

| Prędkość | 35-125 karton/min | ||

| Całkowita moc | 1.10 KW | ||

| Moc SZakład | 220/380V 50Hz | ||

| Wymagania kartonu | Zakres wielkości kartonu:L(65-150)*W(35-85)*H(12-45)mm | ||

| waga kartonu:240-360G/?O | |||

| REquirents of Instrukcje | Zakres wielkości instrukcji:L(78-250)*W(85-170)mm | ||

| Zakres składanych czasów instrukcji:1-4 zginać | |||

| Waga instrukcji:60-70G/?O | |||

| Ciśnienie | intensywność ciśnienia:≥0.6MPA | ||

| zużycie powietrza:120-160 L/min | |||

| Ogólny rozmiar maszyny | 2150*1140*1800?L | ||

| Waga netto maszyny | about 1500kg | ||

High intelligence,accurate loading monitoring.Detection points are densely distributed in various workplaces, such as feeding, quantity detection , packaging into conveyor belt, number of packages, carton in place and so on. The whole process of inspection and result detection is monitored through the process.

All spare part are engraved with codes,convenient maintenance and repair.