ZP 25 55 Automatic Rotary Tablet Press Machine High Speed Two Layer Double Color

자세한 제품 설명 제품 이름:Fully Automatic Rotary Tablet Press MachineItem Type:Tablet Pill Press MachineWarranty:3 YearPower Supply:380/220V 50HzCapacity:115000 Pcs/hPressure:120KNHighlight:High Speed Rotary Tablet Press Machine, Double Color Tablet Press MachineZP 25 55 Automatic Rot…

- 추정 배송 : 7 날 빠른 배송

- 인증 : CGMP CE ISO SGS 등

- 애프터 송금 제공 : 해외 서비스 기계에 이용할 수있는 엔지니어.

| 자세한 제품 설명 | |||

|---|---|---|---|

| 제품 이름: | Fully Automatic Rotary Tablet Press Machine | ||

| 항목 유형: | 태블릿 알약 프레스 머신 | ||

| 보증: | 3 년도 | ||

| Power Supply: | 380/220V 50Hz | ||

| Capacity: | 115000 Pcs/h | ||

| Pressure: | 120kn | ||

| 가장 밝은 부분: |

High Speed Rotary Tablet Press Machine, Double Color Tablet Press Machine |

||

ZP 25 55 Automatic Rotary Tablet Press Machine High Speed Two Layer Double Color

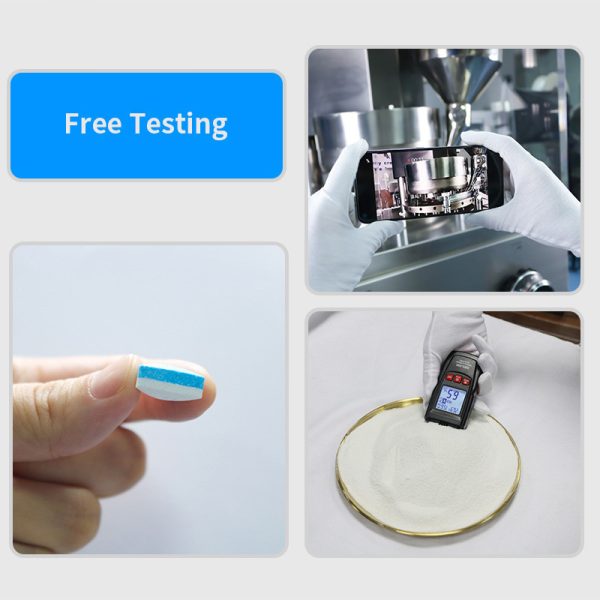

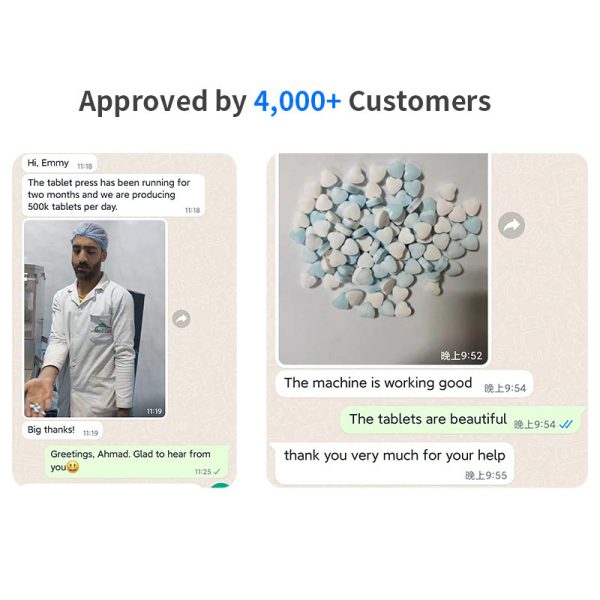

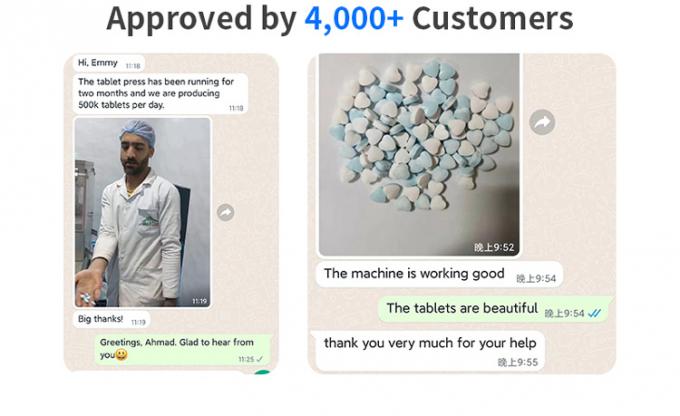

ZP 25 55 tablets press automatic industrial is around nine working days delivery, Free Guaranteed For 3 Years, as 115,000 double layer tablets one hour of making pill making machine press machine to make many kinds Pill Tablets, can include the two color, ring, double layer. pharmaceutical tablets press machinees We company have Passed all of the CE, ISO, SGS, GMP and cGMP.

The selection and design of equipment, in order to ensure production efficiency, should be selected during the production process The equipment that is convenient for cleaning and disinfection ensures that the raw materials and tablets are not contaminated, thus affecting the quality of the tablets.

?? Control the dose of the tablets formulation. The dosage requirements of different tablets are different, by choosing dies with different punch diameters, such as 6 mm, 8 mm, 11.5 mm, 12 mm, etc. After the size of the die is selected, the actual length of the die hole can be changed by adjusting the depth of the lower punch extending into the die hole, and the filling volume of the medicine in the medicine hole can be adjusted.

?? Control the thickness and compaction of the tablet. The dosage of the medicine is determined by the prescription and pharmacopoeia and cannot be changed. In order to meet the requirements of storage, storage and disintegration time limit, tablets compression requires a certain pressure, which will also affect the actual thickness and appearance of the tablet. Pressure must be adjusted during tablets compression. This is achieved by adjusting the amount of of the upper punch in the die hole.