자동화 된 단일 블록 제약 액체 하드 캡슐 충전 생산 기계

Detailed Product DescriptionAfter-sales Service Provided:Automated Monoblock Pharmaceutical Liquid Hard Capsule Filling Machines,capsule Production MachineCondition:NewType:Automated Monoblock Capsule Liquid Filling And Sealing MachinesApplication:Liquid Hard Capsule Filler And SealerVoltage:220V/38…

- 추정 배송 : 7 날 빠른 배송

- 인증 : CGMP CE ISO SGS 등

- 애프터 송금 제공 : 해외 서비스 기계에 이용할 수있는 엔지니어.

| 자세한 제품 설명 | |||

|---|---|---|---|

| After-sales Service Provided: | Automated Monoblock Pharmaceutical Liquid Hard Capsule Filling Machines,capsule Production Machine | ||

| Condition: | New | ||

| Type: | Automated Monoblock Capsule Liquid Filling And Sealing Machines | ||

| Application: | Liquid Hard Capsule Filler And Sealer | ||

| Voltage: | 220V/380V | ||

| Automatic Grade: | Automatic | ||

| 보증: | 2 년도 | ||

| Feature: | Fully Automatic Production Line | ||

| 힘: | 5KW | ||

| Capacity: | 18000pcs/h | ||

| Making Rate: | Empty Capsule 99.9% Full Capsule 99.8% | ||

| Filling Error: | ??2% | ||

| 가장 밝은 부분: |

liquid capsule filler, capsule liquid filling and sealing machine |

||

Automated Monoblock Pharmaceutical Liquid hard Capsule Filling production Machine

제품 세부 사항:

production workshop:

Typical client:

Company Profile:

| 자세한 제품 설명 |

|---|

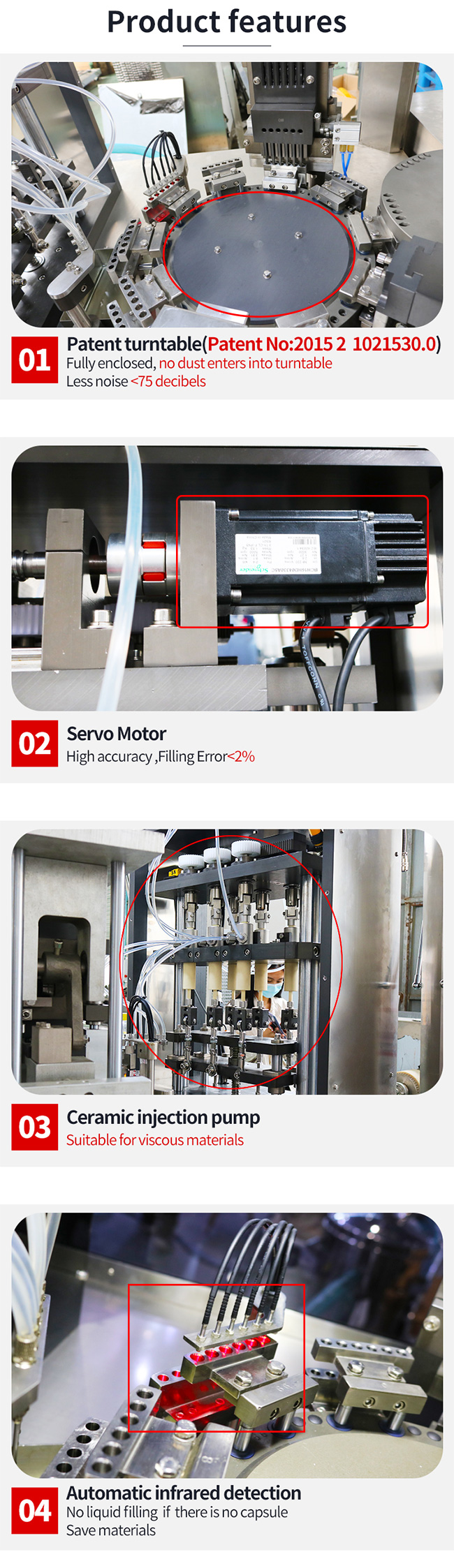

NJYF-300C,new fully automatic monoblock hard capsule filling and sealing machine production line specially designs for filling liquid, with accurate loading and good sealing, improves the safety of the products in the process of storage, transportation and clinical application of products. Liquid drugs such as oily solution, solution, suspension and paste can be canned. The capsules can be made by gelatin capsules, hydroxypropyl methylcellulose (HPMC) and plant capsules according to the actual needs of customers. It can realize the automatic and continuous broadcast capsule, divided the capsule, filling, locking, waste removing and testing online, product output ect., with the load precision (+ – 1-2%),has the advantages of stable operation, no liquid leakage, in keeping with the requirements of GMP production is low, the bio-availability of poorly soluble drugs (poor water solubility), the preferred equipment of low melting point, low drug canned drug dose or potent drugs, hygroscopic drugs