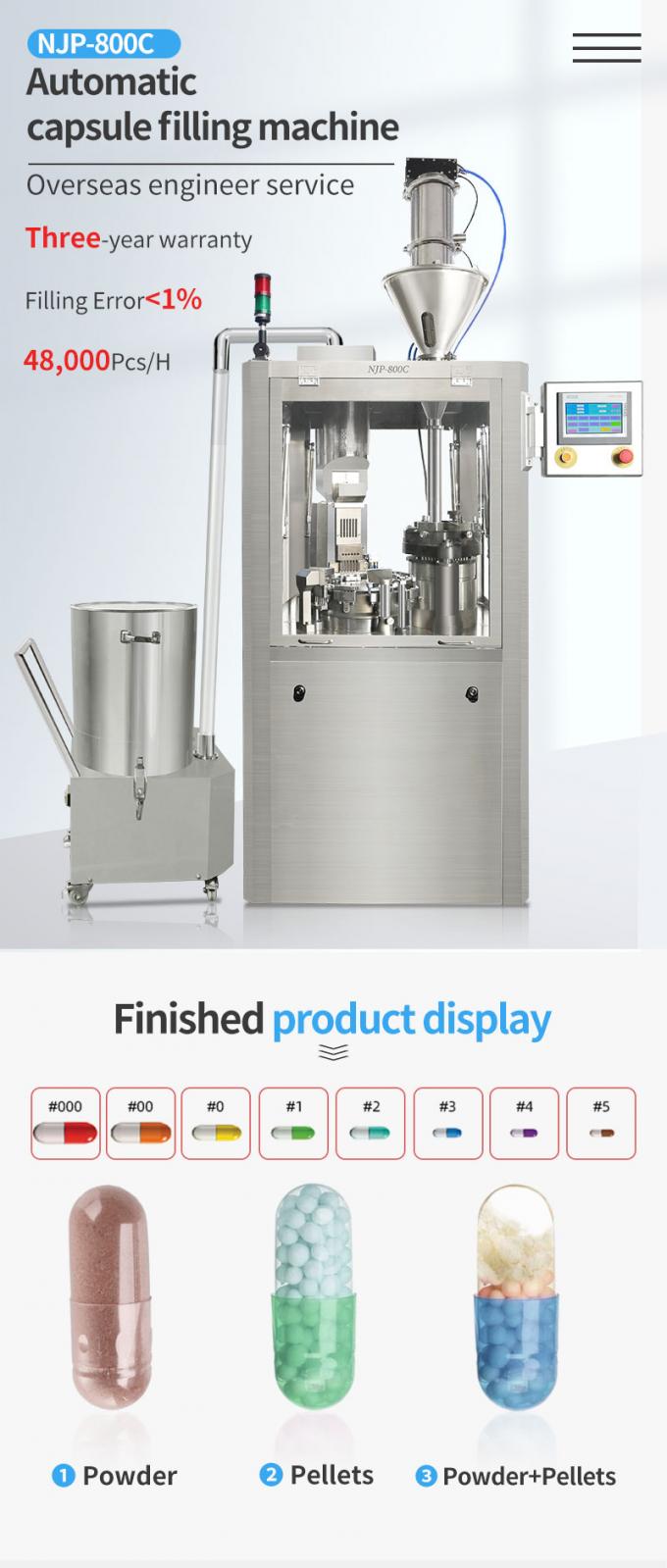

NJP800 auto capsule filling machine 000 capsule manufacturing machine

Detailed Product DescriptionAfter-sales Service Provided:Engineers Available To Service Machinery Overseas,Video Technical Support,Online SupportCapsule Size:000 00 0 1 2 3 4 5Vacuum:20m3/h-0.04-0.08MpaDimension(l*w*h):865*855*1900(mm)Condition:NewWeight:900KGType:Filling MachineCapacity:48000 Capsu…

- 추정 배송 : 7 날 빠른 배송

- 인증 : CGMP CE ISO SGS 등

- 애프터 송금 제공 : 해외 서비스 기계에 이용할 수있는 엔지니어.

| 자세한 제품 설명 | |||

|---|---|---|---|

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas,Video Technical Support,Online Support | ||

| Capsule Size: | 000 00 0 1 2 3 4 5 | ||

| Vacuum: | 20m3/h-0.04-0.08Mpa | ||

| Dimension(l*w*h): | 865*855*1900(mm) | ||

| Condition: | New | ||

| 무게: | 900KG | ||

| Type: | Filling Machine | ||

| Capacity: | 48000 Capsules/h | ||

| Voltage: | 220V/380V 50 HZ | ||

| Automatic Grade: | Automatic | ||

| Driven Type: | Electric | ||

| Packaging Type: | Capsule | ||

| 힘: | 5KW | ||

| 보증: | 1 년도 | ||

| Noise: | <75DB(A) | ||

| 가장 밝은 부분: |

automatic capsule filler, auto capsule filling machine |

||

NJP800 auto capsule filling machine 000 capsule manufacturing machine

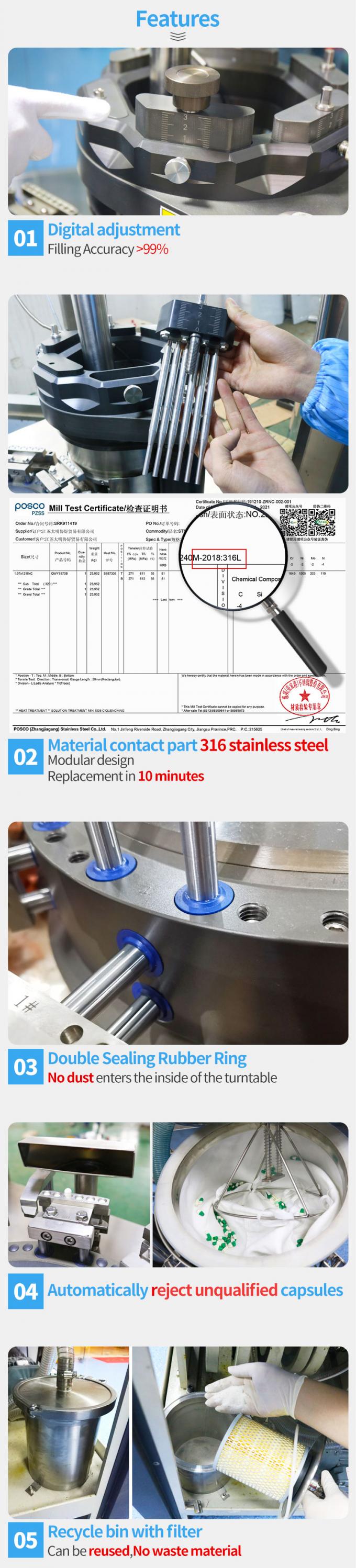

This pharmaceutiacl automatic capsule filling meets the GMP requirements, it is an ideal equipment for filling Chinese, Western medicines and health care product .The other seals of capsule filler machines use the imported SIL silicone rubber sealing ring to block the powder into the bearing, which effectively solves the problem of the card machine that the powder enters the bearing.The separation device of pharmacy machinery has been innovated to separate the powder from the waste capsule and avoid the pollution of the reclaimed powder. (Optional)

With rich experiences in pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipments including tablet press, soft and hard blister packing machine, capsule filling machines, counting machine and cartoning box machine, etc.

| 자세한 제품 설명 | |||

|---|---|---|---|

| Production capacity | 48000 pcs/h | ||

| Net weight of machine | 900Kg | ||

| Overall size of machine | 865×855×1900(mm) | ||

| 힘 | 380/220V 50Hz | ||

| Total power | 5KW | ||

| No.of segment bores | 6 | ||

| Vacuum | 20m3/h-0.04-0.08Mpa | ||

| Dust collector | 17.6Kpa 180m3/h | ||

| Noise | <75DB(A) | ||

| Making rate | Empty capsule 99.9% Full capsule 99.8% | ||

| Applicable capsule | 00,0,1,2,3,4,5# | ||

| Filling error | Western medicine:±3% Chinese medicine:±4% | ||

| Applicable product | 힘,granule,pellet,tablet | ||

The data comes from Guangdong Rich Packaging Machinery Co., 주식회사

제품 세부 사항:

제작 워크숍:

Global after-sales service:

Turntable and mold: the capsule is all stainless steel 316L in the upper and lower moulds, and the material is more resistant to corrosion and durability

1.Pharmacy capsule filling equipment can fill powder, granules and other materials into hollow capsules (000#, 00#, 0#, 1#, 2#, 3#, 4#, 5#).

2.The capsule filling machine of Guangdong Rich Packing Packing Machinery Co. 주식회사. has reasonable design,modular structure, easy operation and lower failure rate.

3.With rich experiences in pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipments including tablet press, soft and hard blister packing machine, capsule filling machines, counting machine and cartoning box machine, etc.

4.When we are manufacture the capsule filling machines ,the filling rod, the upper and lower die holes, the measuring disk adapt non polar electronic polishing treatment, enhance the material fluidity, which has solved the problems of sticky of material, stick with mold and easy to absorb moisture. (According to the material properties and the special requirements of customers, Guangdong Rich Packing Machinry Co. Ltd can provide the Teflon coating processing service)

5.This series capsule filling machinery capsule suction, capsule outlet, locking and waste rejection adapt double sealing device, one is imported NBR sealing rubber which prevents the loss of lubricating oil.