ペレット顆粒長寿命のための半自動カプセル充填機

提供される販売後の詳細な製品の説明:海外で機械のサービスを提供できるエンジニア,ビデオ技術サポート,Online SupportMax.Capacity:15000-28000pcs/hType:Filling MachinePower Supply:2.12kwPower:220V/380V 50HzOutline Dim.:1300*800*1750mmGross Weight Of Machine:500 KgWarranty:…

- 配達予定日 : 7 数日での迅速な配達

- 認証 : cGMP CE ISO SGS など

- アフターサービスの提供 : 海外でも機械の修理に対応できるエンジニア.

| 詳細な製品説明 | |||

|---|---|---|---|

| 提供されるアフターサービス: | 海外で機械のサービスを提供できるエンジニア,ビデオ技術サポート,オンラインサポート | ||

| Max.Capacity: | 15000-28000PCS/h | ||

| タイプ: | Filling Machine | ||

| Power Supply: | 2.12KW | ||

| 力: | 220V/380V 50Hz | ||

| Outline Dim.: | 1300*800*1750mm | ||

| Gross Weight Of Machine: | 500 Kg | ||

| 保証: | 12 Momths | ||

| ハイライト: |

semi automatic capsule filler, semi auto capsule filler |

||

ペレット顆粒長寿命のための半自動カプセル充填機

| 詳細な製品説明 | |||

|---|---|---|---|

| モデル | CGN-208 | ||

| Max.Capacity | 15000-28000PCS/h | ||

| 適用されるカプセル | 00#,0#,1#,2#,3#,4#,5# | ||

| 電源 | 2.12KW | ||

| 力 | 380V/50Hz | ||

| Outline dim. | 1300*800*1750mm | ||

| マシンの正味重量 | 400kg | ||

| Gross weight of machine | 500 kg | ||

| Packing size | 1640*720*1700mm | ||

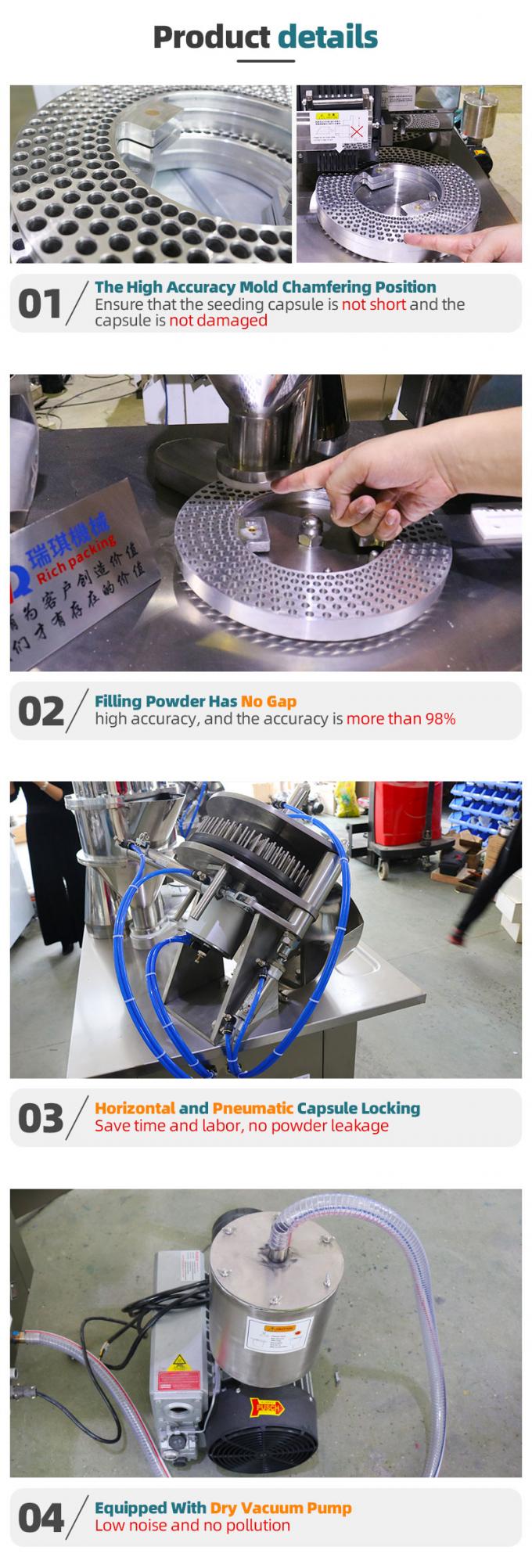

Product details:

Production workshop:

Global after-sales service:

1.The manaual capsule filling machine can be used for filling 000, 00, 0, 1, 2, 3, 4 and 5 standard capsules.

2.The structure of the semi capsule filling machine is novel, the structure of the capsule locking is improved, saves labor, improves work efficiency, has beautiful appearance and meets the requirements of GMP production.

3.1.The manual automatic capsule filling machine is easy to operate and stable operation.

4.The semi automatic capsule filling machine is equipped with capsule sowing protection device and emergency stop device to ensure the safety of the operator.

5.Equip with Siemens PLC device, touch screen operation, semi automatic capsule filling machine is convenient for usage, while prolonging the service life.

6.By controlling the loading speed and the rotary speed of the capsule plate, the filling dose is accurate and the error can be kept within 3%. 7.Automatic filling, effective prevention of drug pollution, meet the requirements of GMP.