Electric Automatic Capsule Filler With 12 月の保証

詳細な製品説明名前:NJP 1200 Automatic Control Capsule Filling Machine ManufacturerAfter-sales Service Provided:海外で機械のサービスを提供できるエンジニア,ビデオ技術サポート,Online SupportCapacity:72000 Capsules/hourVoltage:220V/380V 50HzDimension(l*w*h):900*870*1950mmCondi…

- 配達予定日 : 7 数日での迅速な配達

- 認証 : cGMP CE ISO SGS など

- アフターサービスの提供 : 海外でも機械の修理に対応できるエンジニア.

| 詳細な製品説明 | |||

|---|---|---|---|

| 名前: | NJP 1200 Automatic Control Capsule Filling Machine Manufacturer | ||

| 提供されるアフターサービス: | 海外で機械のサービスを提供できるエンジニア,ビデオ技術サポート,オンラインサポート | ||

| 容量: | 72000 Capsules/hour | ||

| 電圧: | 220V/380V 50Hz | ||

| 寸法(l*w*h): | 900*870*1950mm | ||

| 状態: | 新しい | ||

| 自動グレード: | 自動 | ||

| 重さ: | 1100KG | ||

| タイプ: | Filling Machine | ||

| 保証: | 12 Months | ||

| 力: | 5.5KW | ||

| Driven Type: | Electric | ||

| ハイライト: |

自動カプセルフィラー, pill filler machine |

||

NJP 1200 Automatic Control Capsule Filling Machine Manufacturer

Introduction of capsule filling machine:

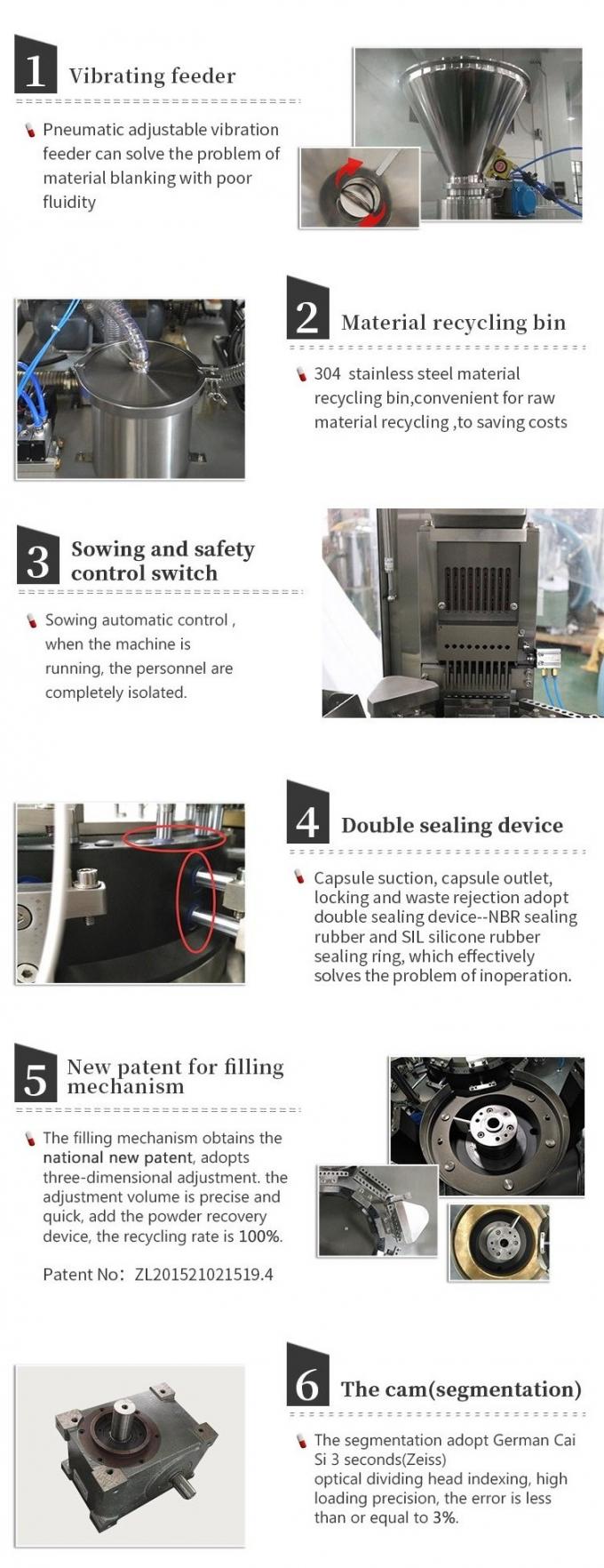

The filling speed of the capsule filling machine is fast, and the difference of the size of the capsule filling machine is small. The filling of the capsule shell, the capsule cap finishing, and the capsule set are integrated, which is compact and convenient. In addition, the capsule filling machine has many advantages such as high speed, high efficiency, simple operation, convenient maintenance and low power consumption. It is the preferred capsule filling (filling) machine for pharmaceutical factories, health care products factories and hospital preparation rooms.

Features of capsule filling machine:

1.This pharmaceutiacl automatic capsule filling meets the GMP requirements, it is an ideal equipment for filling Chinese, Western medicines and health care product .

2.This automatic capsule fill machines can automatically finish the production process including sowing, capsule separating, filling, locking, unqualified capsule rejected and finished products output.

3.This pharmaceutical capsule filling machine has safety firs, all the working stations take full account of the personal safety, such as the door control and emergency stop switch.

4. Guangdong Rich Packing Machinery Co. Ltd.'s capsule filler machine deploy segmentation adapt German Cai Si for 3 秒 (Zeiss) 光学分割ヘッドインデックス, インデックス作成シャフトは1回限りの処理を完了しました, 読み込みと高精度,

エラーは等しくありません 3%.

5.The capsule filler machines use the imported SIL silicone rubber sealing ring to block the powder into the bearing, which effectively solves the problem of the card machine that the powder enters the bearing.

| 詳細な製品説明 | |||

|---|---|---|---|

| 生産能力 | 72000 PCS/h | ||

| マシンの正味重量 | 1100Kg | ||

| マシンの全体的なサイズ | 900×870×1950 | ||

| 力 | 380/220V 50Hz | ||

| 総電力 | 5.5KW | ||

| No. ofセグメントボア | 9 | ||

| 真空 | 40M3/h-0.04-0.08MPA | ||

| ダストコレクター | 24.5Kpa 210m3/h | ||

| ノイズ | <75DB(a) | ||

| 作成レート | 空のカプセル 99.9% フルカプセル 99.8% | ||

| 適用されるカプセル | 00,0,1,2,3,4,5# | ||

| 充填エラー | 西洋医学:±3% 漢方薬:±4% | ||

| 適用される製品 | 力,顆粒,ペレット,錠剤 | ||

| 重さ | 1100Kg | ||

| Packing size | 1490×1260×2150mm | ||

6.equipped with on-line air pressure die cleaning system, the upper and lower dies are clean and without dust, improve the sowing effect.

The capsule filler machinery is precision mold concentricity, zero deviation, ensure that the capsule is not wiping, no damage.

7.Automatic rejection device, improve the charging efficiency ,the capsule filling equipment is suitable to pharmacy and health care food manufacture.

8.The control of capsule filler machine appliance adopts the world famous brand, modularized setup, convenient inspection and maintenance, SIEMENS human machine interface, real-time counting, and can print the equipment according to customer needs, print production date, batch number, code, 等.

8.あなたのマシンは私たちのニーズをうまく満たすことができますか?

私たちはあなたの特定の要件に関する提案を提供します, and each machine is customized to satisfy customer's need well.

9.What's your payment way?

T/T by our bank account directly, or L/C, or by the West Union, or in cash.

10.Rotary of capsule filling machine design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow

pollution