Cartonatura di blister tablet automatico a capsule

Detailed Product DescriptionSpeed:125 Carton/minTotal Power:0.750 KWPower Supply:380V 50HzRequirements Of Carton:Carton Weight:250-350g/?OOverall Size Of Machine:4300*1100*1550?LHighlight:high speed packaging machines, automatic capsule fillerAutomatic Capsule Tablet Blister Cartoning Machine RQ-ZH-…

- Estimated Delivery : 7 Days Fast Delivery

- Certificazione : cGMP CE ISO SGS and etc

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| Speed: | 125 Carton/min | ||

| Total Power: | 0.750 KW | ||

| Power Supply: | 380V 50Hz | ||

| Requirements Of Carton: | Carton Weight:250-350g/?O | ||

| Overall Size Of Machine: | 4300*1100*1550?L | ||

| Evidenziare: |

high speed packaging machines, automatic capsule filler |

||

Cartonatura di blister tablet automatico a capsule

RQ-ZH-120W Automatic Horizontal Cartoning Packing Machine is a multi-functional product integrating light and electricity developed by Guangdong Rich Packing Machinery Co.,Ltd in recent years. It can automatically and quickly pack aluminum plastic board, electronic cigarette, facial cleanser, ointment, soft bag, bottle, powder, granule bag, condom, soft double-layer aluminum, gypsum, coffee, mask and etc.It high integration,this automatic horizontal cartoning packing machine can be connected with tail sealing machine,aluminum plastic blister packing machine,strapping machine according to customers’ production requirements.

| Detailed Product Description | |||

|---|---|---|---|

| After-sale Provide | Engineers Available To Service Machinery Overseas | ||

| Cartoning Machine Models | 120W | 260W | 450W |

| Power | 0.75 Kw | 5 Kw | 4.5 Kw |

| Capacity | 120 Carton/Min | 260 Carton/Min | 450 Carton/Min |

| Dimension | 3100*1100*1550 mm | 6800*1600*1860 mm | 4800*1800*2000 mm |

| Peso | 1600 Kg | 3400 Kg | 5500 Kg |

| Detailed Product Description | |||

|---|---|---|---|

| Spare Parts Name | Specification | Qty. | Manufacturer |

| Servo Motor | 400W MHMD042G1U | 1 | Panasonic |

| Servo Driver | 400W MBDHT2510E | 1 | Panasonic |

| Main Motor | R17DT80N4 1.1KW/220V/380V | 1 | Germany SEW |

| Vacuum Pump | VT4.40 | 1 | BECKER |

| Frequency Converter | FC-051P1K5S2E20H | 1 | Danfoss |

| Air Circuit Breaker | DZ47-D63/2P | 1 | Yaohua |

| PLC | Smart ST40 | 1 | Siemens |

| Emergency Stop Button | ZB2-BE102C | 1 | France Schneider |

1.Double clutch design

When the main motor overload or folding machine failure, start protection function to ensure the safety of equipment and personnel.

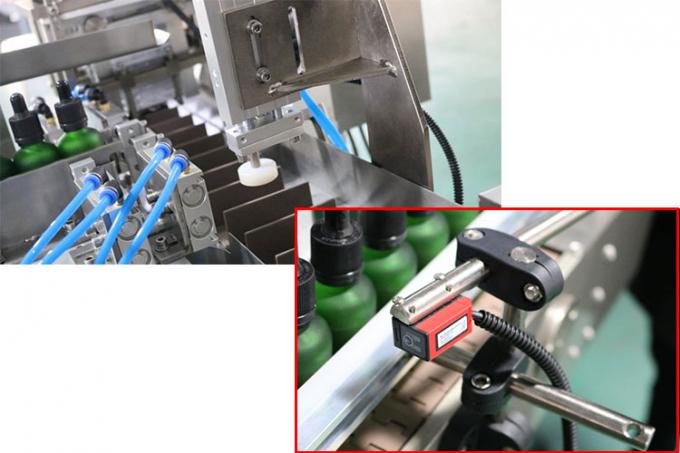

2.Multiple detection points

Detection points are densely distributed in various workplaces, such as feeding, quantity detection , packaging into conveyer belt, number of packages, carton in place and so on.

3.Back-push feeding

Convenient for front-end operation