29 Punch Pill Powder Tablets Presser Automatic Large Diameter Tablet Press Machine

Deskripsi Produk Detail Nama:29 Punch Pill Powder Tablets Presser Automatic Large Diameter Tablet Press MachineDies No.:29 SetMax. Kapasitas produksi:75000 Pcs/hMax.?Tekanan:100KNMax.?Dia. Of?Tablet:25mmMax. Depth Of Filling:24mmMax.?Thickness Of Tablet:12mmDia. Of Middle Die:38.1mmLength Of U…

- Perkiraan pengiriman : 7 Hari pengiriman cepat

- Sertifikasi : CGMP CE ISO SGS dan dll

- Setelah penjualan disediakan : Insinyur tersedia untuk mesin layanan di luar negeri.

| Deskripsi produk terperinci | |||

|---|---|---|---|

| Nama: | 29 Punch Pill Powder Tablets Presser Automatic Large Diameter Tablet Press Machine | ||

| Dies No.: | 29 Set | ||

| Max. Kapasitas produksi: | 75000 PC/H. | ||

| Max.?Tekanan: | 100KN | ||

| Max.?Dia. Of?Tablet: | 25mm | ||

| Max. Depth Of Filling: | 24mm | ||

| Max.?Thickness Of Tablet: | 12mm | ||

| Dia. Of Middle Die: | 38.1mm | ||

| Length Of Upper/Lower Punching Bar: | 115mm/133.4mm | ||

| Dia.of Upper/Lower Punching Bar: | 25.4mm | ||

| Rotary Speed: | 5??21 R/min | ||

| Motor: | 5.5kw | ||

| Weight Of Machine: | 1600kg | ||

| Outline Dim.: | 1040??910??1690mm | ||

| Menyorot: |

Pill Powder Tablets Presser, 100KN Rotary Tablet Press Machine |

||

29 punch pill powder tablets presser automatic large diameter tablet press machine

Product details:

Production workshop:

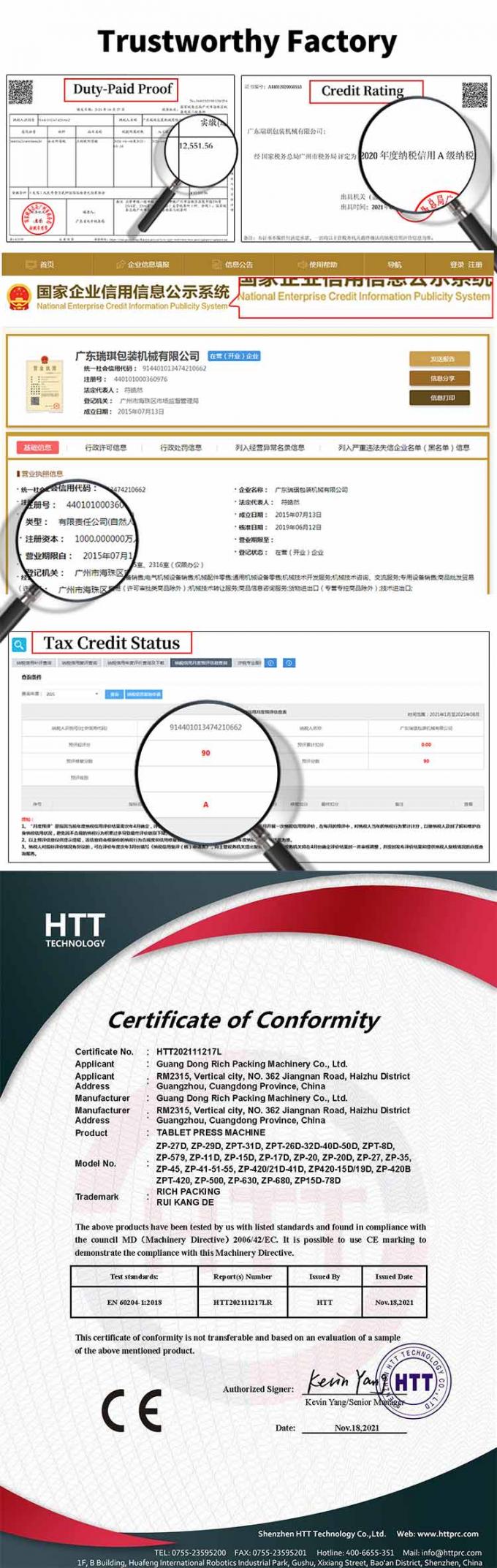

Certificate:

ZP-29D is a automatic rotary large diameter tablet press machine ,continuously pressing powder and particle into round tablets, special-shaped tablets, double color and annular tablet. It is the preferred product in pharmaceutical, chemical, electronics, food and other enterprises in production, it is also suitable for pressing that material that is difficult formed into tablet, meet the requirements of GMP production.