DPP-160r GMP Requirements Thermoforming Alu Pvc Blister Packaging Machine

Detailed Product DescriptionProduction Capacity:4200 Pellets Per HourMax. Shaping Dia. And Depth:130*100*15mm Max. Depth 26mm??custom-made??Blanking:20??50 Times/minTotal Power:3.78kWStandard Plate:80*57mmStandard Travel Range:40??110mmNoise:Product:DPP-160 Plate Tablet Capsule Pill Automatic Blister P…

- Estimated Delivery : 7 Days Fast Delivery

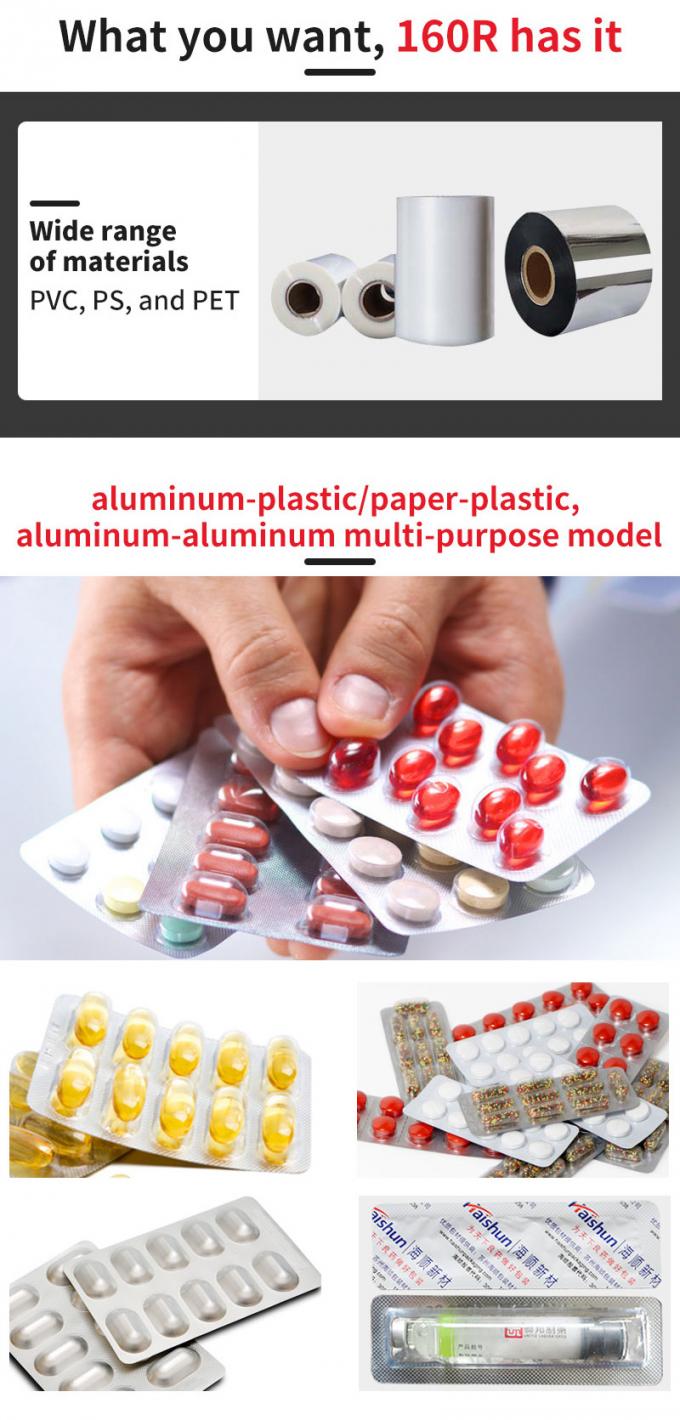

- प्रमाणीकरण : cGMP CE ISO SGS and etc

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| Production Capacity: | 4200 Pellets Per Hour | ||

| Max. Shaping Dia. And Depth: | 130*100*15mm Max. Depth 26mm??custom-made?? | ||

| Blanking: | 20??50 Times/min | ||

| Total Power: | 3.78kW | ||

| Standard Plate: | 80*57mm | ||

| Standard Travel Range: | 40??110mm | ||

| Noise: | <75dBA | ||

| Product: | DPP-160 Plate Tablet Capsule Pill Automatic Blister Packing Machine | ||

| Voltage: | 380V/220V 50Hz | ||

| Warranty: | 24 Months | ||

| प्रमुखता से दिखाना: |

Pvc Blister Packaging Machine, Thermoforming Blister Packaging Machine |

||

| Detailed Product Description | |||

|---|---|---|---|

| Model | DPP-160r | ||

| Punching times | 20??50 times/min | ||

| Production capacity | 36000-72000 grains/hour | ||

| Maximum forming area and depth | 130*100*15mm | ||

| Maximum depth up to | 26mm (customized) | ||

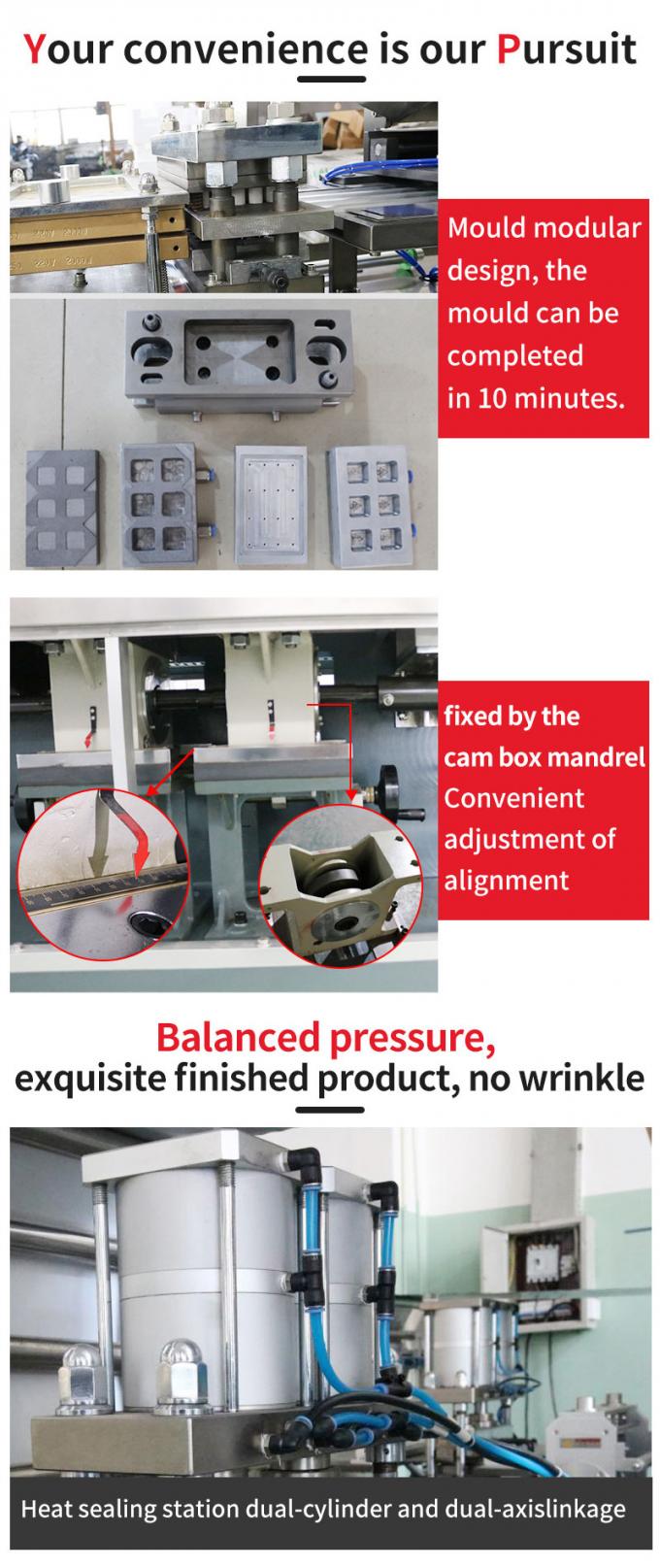

1. The three stations of forming, heat-sealing and punching are all fixed by cam box mandrel, unified horizontal positioning reference and adjustment scale, convenient for customers to adjust the alignment.

2. The three stations of forming, heat sealing and blanking are equipped with safety covers to protect the safety of operators.

3. The material of this machine has a wide range of applications, not only PVC, PS, but also PET and other materials can be used for production.

4. This machine is equipped with blanking dislocation, photoelectric detection and automatic shutdown function, this machine protects the mold and the product.

5. The PVC feeding of this machine is detected by photoelectricity and driven by a motor. The feeding amount is accurate, the traction pressure is reduced, and the overall running speed of this machine is faster.

6. The heat-sealing station of this machine adopts dual-cylinder and dual-axis linkage, and the pressure is large and balanced. The combination of PVC and aluminum foil of this machine is good, with clear lines and no wrinkles.

7. This machine adopts a new type of helical gear reducer motor, and the equipment runs stably.

8. The four-position cams of this machine, forming, heat-sealing, indentation, and punching, are made of cast steel integrally formed floor-standing box body seat, which will never be deformed, and the center of gravity of the machine's operation is stable, and each station is adjusted Lightweight and accurate.

9. 160 aluminum-plastic blister packaging machine This machine adopts a large platform design, and the power transmission and cam box are all built-in under the body, which is convenient for cleaning and maintenance of the machine after use.

10. The PVC and PTP fragments of this machine will stop and automatically alarm, which improves the efficiency of raw material utilization.