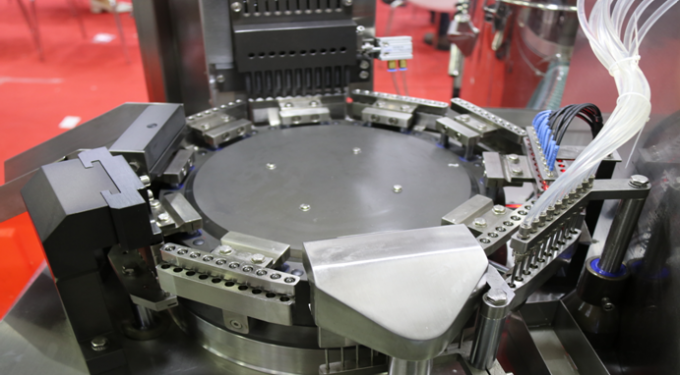

Fully Automatic Liquid Capsule Filling Machine No Liquid Drip Capacity 100 Pcs/h

Detailed Product DescriptionProduct Name:Fully Automatic Capsule Liquid Filling MachineItem Type:Capsule Filling MachineApplicable Capsule:000-3# Gelatin Capsule, Methyl Cellulose, Plant CapsuleProduct Capacity:100 Pcs/hPower Supply:380/220V 50HzMotor Power:3.5 KwDimension:700*800*1700mmWeight:500 K…

- Livraison estimée : 7 Jours de livraison rapide

- Certification : cGMP CE ISO SGS et etc.

- Service après-vente assuré : Ingénieurs disponibles pour entretenir les machines à l’étranger.

| Description détaillée du produit | |||

|---|---|---|---|

| Product Name: | Fully Automatic Capsule Liquid Filling Machine | ||

| Item Type: | Machine de remplissage de capsule | ||

| Applicable Capsule: | 000-3# Gelatin Capsule, Methyl Cellulose, Plant Capsule | ||

| Product Capacity: | 100 Pcs/h | ||

| Power Supply: | 380/220V 50 Hz | ||

| Motor Power: | 3.5 Kw | ||

| Dimension: | 700*800*1700mm | ||

| Poids: | 500 Kilogrammes | ||

| Garantie: | 1 Année | ||

| After-sale: | Ingénieurs disponibles pour entretenir les machines à l’étranger | ||

| Souligner: |

liquid capsule filler, capsule liquid filling and sealing machine |

||

| Description détaillée du produit | |||

|---|---|---|---|

| Machine de remplissage de capsule | Machine d'emballage en cloque | Machine à carton automatique | |

No Liquid Drip NJY-100C Fully Automatic Capsule Liquid Filling Machine

This series of products has accurate loading and good sealing, which improves the safety of the products in the clinical application of storage, transportation and product medicine. This product has a wide range of applicability, liquid drugs such as oily liquid, solution, suspension, paste, etc.. can be canned, capsules can be according to the actual needs of customers, in (00-3#) gelatin capsules, hyprothenol Base cellulose (HPMC), plant capsules are optional. The product can automatically complete the production process of sowing, sub-sac filling, filling, locking capsule, waste rejection, on-line inspection, finished product output, etc.. It has the advantages of accurate loading (+ -, 1-2%), stable operation, no liquid dripping, etc.. In line with GMP production requirements, it is the first choice for low bioavailability poorly soluble drugs (poor water solubility), low melting point drugs, low dose or potent drugs, hygroscopic drugs, and drug cans with high sustained release requirements.

| Description détaillée du produit | |||

|---|---|---|---|