Automatic Rotatry Tablet Press Making Machine 40000 Pieces Per Hour Max. Dia 25mm ZP-20

Detailed Product DescriptionCapacity:40000 Pcs / HourMachine Type:Tablet Pill Press Making MachineTablet Thickness:2-8mmPower:4.0kwIntelligent Lubrication System:USA BeckerMaximum Tablet Diameter:25mmMaterial:Stainless SteelControl System:PLCPacking Size:1340??1100??1960mm Wooden CaseMachine Dimensi…

- Estimated Delivery : 7 Days Fast Delivery

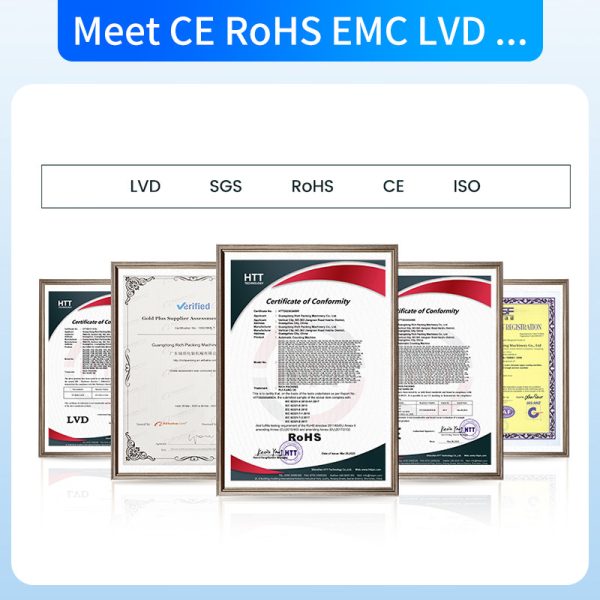

- مجوز : cGMP CE ISO SGS and etc

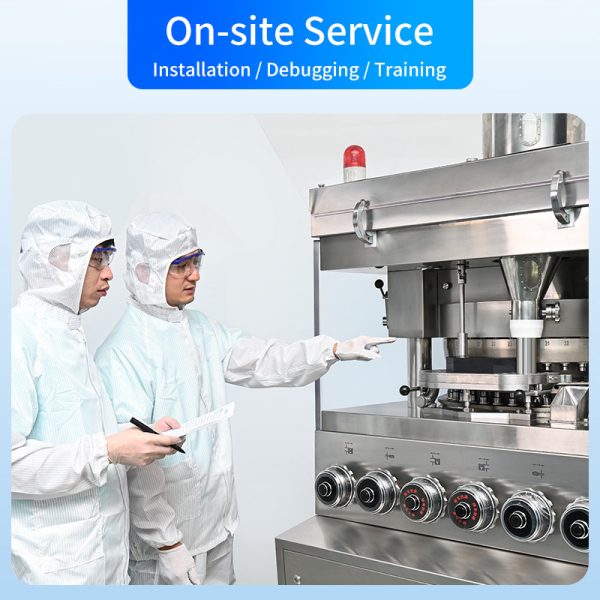

- After-Sales Provided : Engineers available to service machinery overseas.

| Detailed Product Description | |||

|---|---|---|---|

| Capacity: | 40000 Pcs / Hour | ||

| Machine Type: | Tablet Pill Press Making Machine | ||

| Tablet Thickness: | 2-8میلی متر | ||

| Power: | 4.0kw | ||

| Intelligent Lubrication System: | USA Becker | ||

| Maximum Tablet Diameter: | 25میلی متر | ||

| Material: | Stainless Steel | ||

| Control System: | PLC | ||

| Packing Size: | 1340??1100??1960mm Wooden Case | ||

| Machine Dimensions: | 840??1015??1720میلی متر | ||

| برجسته کردن: |

PLC Control Tablet Press Making Machine, Automatic Rotatry Tablet Press Making Machine |

||

ZP-20 Rotary Tablet Press Machine

1. Unmatched Efficiency and Cost Performance

Feature: The ZP-20 boasts a maximum pressure of 80 kN, a pressing diameter of up to 25mm, and a capacity to produce 40,000 tablets per hour.

Advantage: This high-efficiency machine allows for large-scale production without compromising on quality or speed.

Benefit: Maximize your production output and reduce operational costs, ensuring a higher return on investment.

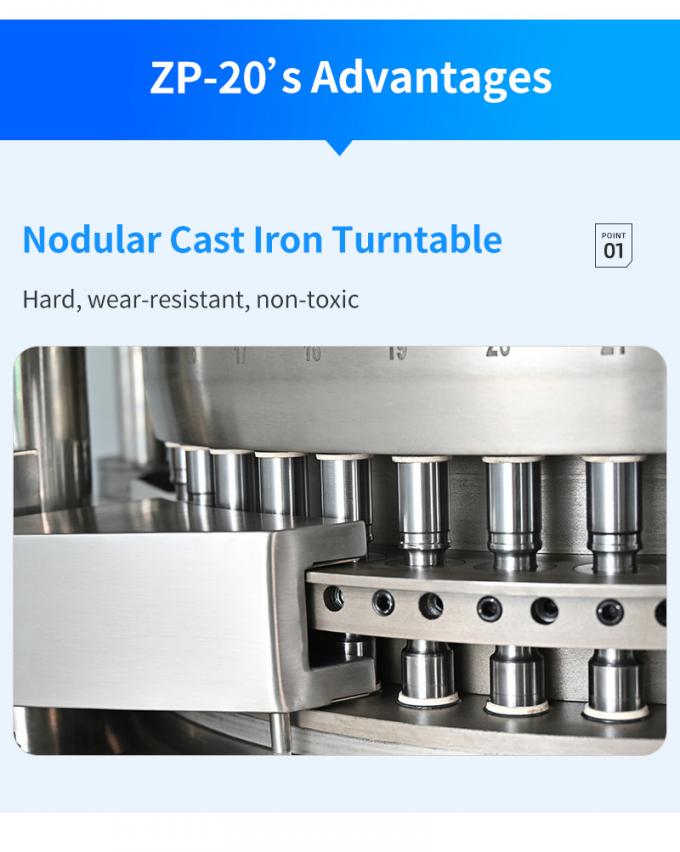

2. Comprehensive GMP Compliance

Feature: The ZP-20 is constructed with a stainless steel shell and an organic glass-enclosed chamber, ensuring excellent sealing and contamination prevention.

Advantage: Every part that comes in contact with the tablet material is non-toxic, odorless, and corrosion-resistant, fully meeting GMP standards.

Benefit: Guarantee the highest standards of safety and quality in your pharmaceutical production, enhancing your product’s market trust and compliance with regulatory requirements.

3. Precision and Stability

Feature: The machine features high-precision components, such as the H8 coaxiality for punches and molds, and a hand wheel with a sensitivity of 0.1mm.

Advantage: This precision engineering ensures consistent tablet weight and thickness, with smooth and stable operation.

Benefit: Achieve superior quality control in tablet production, minimizing waste and rework, and maintaining the integrity of each batch.

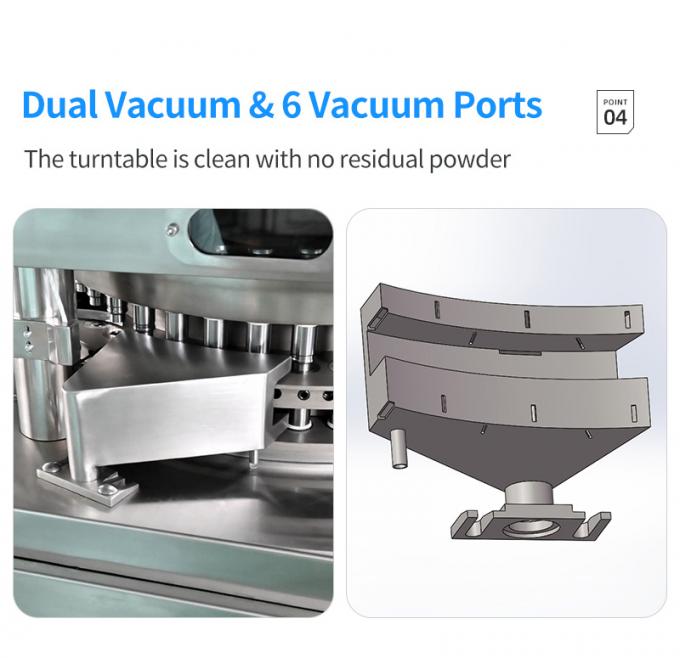

4. Advanced Intelligent Systems

Feature: Equipped with an intelligent lubrication system and pressure overload protection.

Advantage: The lubrication system ensures timely, precise oiling of critical parts, while the overload protection quickly responds to prevent damage.

Benefit: Extend the lifespan of your machine and minimize downtime due to maintenance or repairs, thereby enhancing overall productivity.

5. User-Friendly and Modular Design

Feature: The ZP-20's modular transmission system, large angle platform design, and easy disassembly features.

Advantage: This design prevents contamination, simplifies maintenance, and enhances operational convenience.

Benefit: Reduce cleaning and maintenance time, allowing your staff to focus on production, and ensure a cleaner, more

efficient work environment.

در ZP-20 Rotary Tablet Press Machine is not just a machine; it’s a powerhouse designed to revolutionize your tablet production process. Experience unparalleled efficiency, stringent GMP compliance, precision, intelligent systems, and user-friendly design with the ZP-20. Elevate your production capabilities and secure a competitive edge in your industry today.

| Detailed Product Description | |||

|---|---|---|---|

|

How to Contact Us? |

|||

|

ایمیل |

manager@richpacking.cn | ||

|

WhatsApp & وکت |

+86-138-2609-3596 | ||

|

Visit WebSite |

www.richpacking020.com | ||