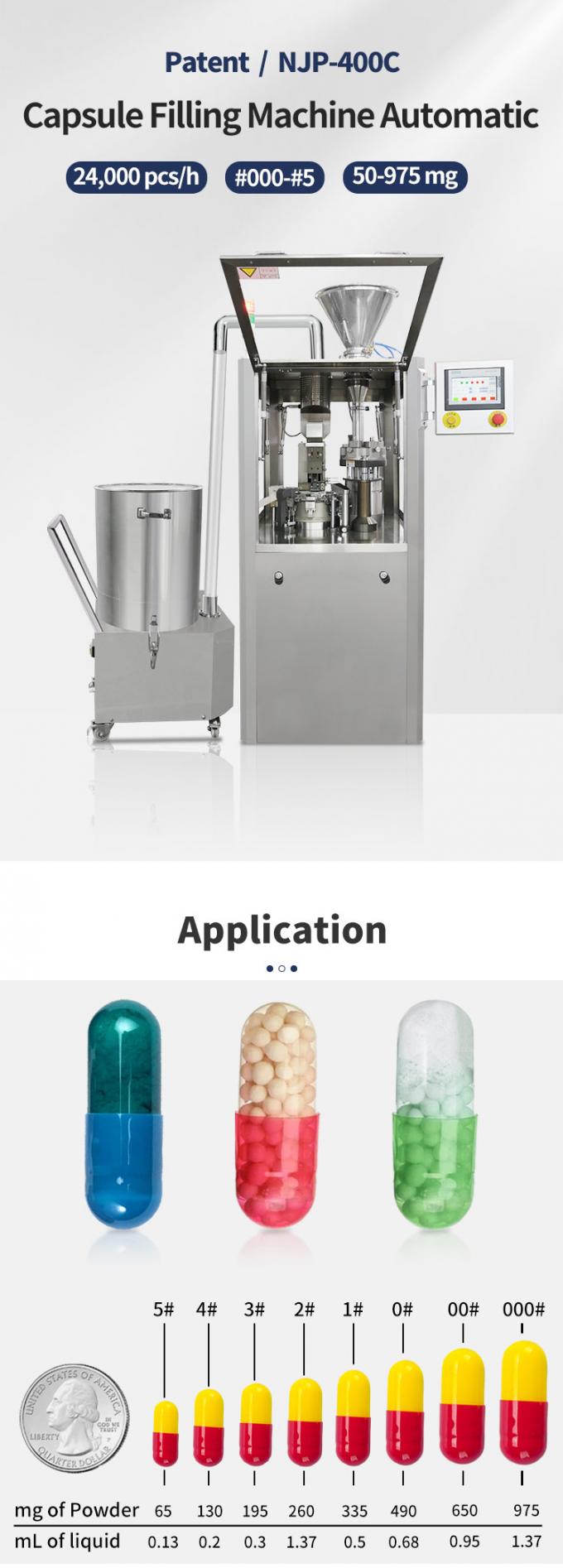

Gelatin Capsule Powder Filling Machine 24000 Pcs Per Hour Capsule Filling Machinery

Detailed Product DescriptionAfter-sales Provided:Engineers Available To Service Machinery OverseasSuitable For Capsule:000,00,0,1,2,3,4,5#Τροφοδοσία:380/220V 50HzMaking Rate:Empty Capsule 99.9%,Full Capsule 99.8%Filling Error:??3%-??4%Αποκορύφωμα:automatic capsule filler, auto capsule filling machine …

- Εκτιμώμενη παράδοση : 7 Ημέρες γρήγορη παράδοση

- Πιστοποίηση : CGMP CE ISO SGS και κλπ.

- Παρέχονται μετά τις πωλήσεις : Οι μηχανικοί είναι διαθέσιμοι σε μηχανήματα εξυπηρέτησης στο εξωτερικό.

| Λεπτομερής περιγραφή προϊόντος | |||

|---|---|---|---|

| After-sales Provided: | Οι μηχανικοί είναι διαθέσιμοι σε μηχανήματα εξυπηρέτησης στο εξωτερικό | ||

| Suitable For Capsule: | 000,00,0,1,2,3,4,5# | ||

| Τροφοδοσία: | 380/220V 50Hz | ||

| Making Rate: | Empty Capsule 99.9%,Full Capsule 99.8% | ||

| Filling Error: | ??3%-??4% | ||

| Αποκορύφωμα: |

automatic capsule filler, auto capsule filling machine |

||

Gelatin Capsule Powder Filling Machine 24000 Pcs Per Hour Capsule Filling Machinery

| Λεπτομερής περιγραφή προϊόντος | |||

|---|---|---|---|

| Καθαρό βάρος μηχανής | 600Kg | ||

| Overall size of machine | 805×705×1760(mm) | ||

| Εξουσία | 380/220V 50Hz | ||

| Total power | 3.5KW | ||

| No.of segment bores | 3 | ||

| Vacuum | 20m3/h-0.04-0.08MPA | ||

| Dust collector | 17.6Kpa 180m3/h | ||

| Noise | <75DB(A) | ||

| Making rate | Empty capsule 99.9% Full capsule 99.8% | ||

| Ισχύουσα κάψουλα | 00,0,1,2,3,4,5# | ||

| Filling error | Western medicine:±3% Chinese medicine:±4% | ||

| Applicable product | Εξουσία,granule,pellet,δισκίο | ||

Λεπτομέρειες προϊόντος:

Εργοστασιακό εργαστήριο:

Global after-sales service:

1.New patent for filling mechanism The filling mechanism obtains the national new patent, adopts three-dimensional adjustment. the adjustment volume is precise and quick, add the powder recovery device, the recycling rate is 100%.Patent No:ZL201521021519.4

2. Design of drawing and clamping slot for filling rodThe design of pulling chute for filling rod can save 60% time by replacing various types of filling rod.

1. Segmentation adapt German Cai Si for 3 seconds (Zeiss) optical dividing head indexing, indexing shaft completed a one-time processing, loading and high precision, the error is less than or equal to 3%.

2. Rotary design to obtain a patent for utility model, the sealing ring using imported SIL silicone rubber, effectively prevent powder into the internal turntable, good sealing performance, no dust overflow pollution; Transverse biaxial adapt PTFE oil-less bearing, no need refueling; modular structure, equipped with jog operation, convenient maintenance and cleaning, replacement of mold only 15 minutes.