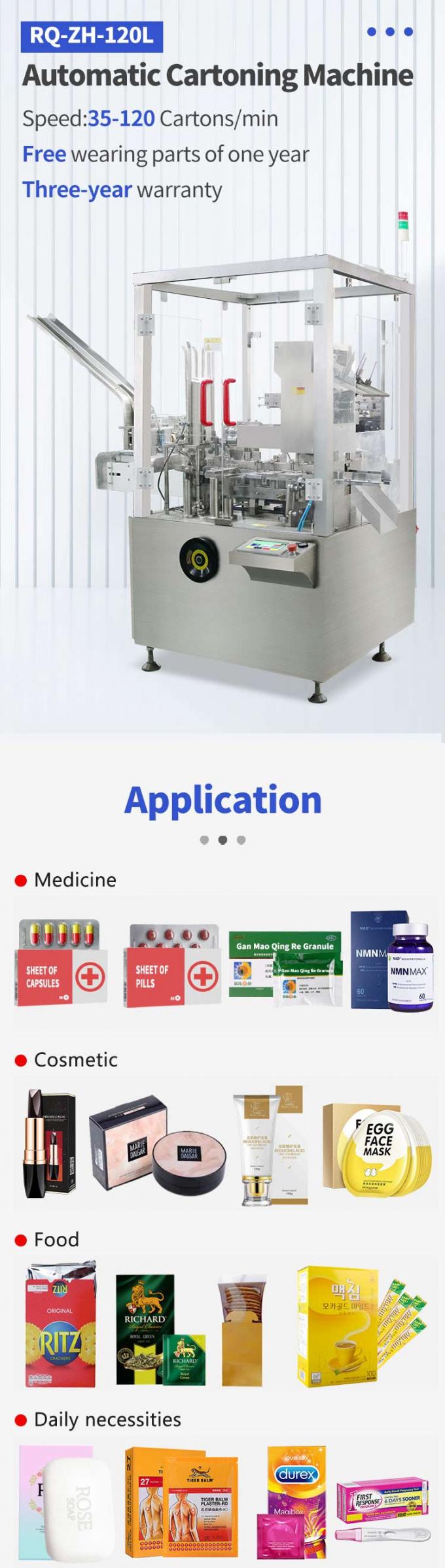

Fully Automatic Carton Box Packaging Packing Cartoning Machine Convenient Maintenance And Repair

Detailed Product DescriptionAfter-sale Provide:Engineers Available To Service Machinery OverseasProduct Name:Automatic Pharmaceutical Cartoning MachineType:Vertical Cartoning MachineProduction:30-120 Cartons/minSize Range Of Carton:L(65-150)*W(35-85)*H(12-45)mmCarton Weight:250-350σολ/?OFunction:Χαρτοκιβώτιο…

- Εκτιμώμενη παράδοση : 7 Ημέρες γρήγορη παράδοση

- Πιστοποίηση : CGMP CE ISO SGS και κλπ.

- Παρέχονται μετά τις πωλήσεις : Οι μηχανικοί είναι διαθέσιμοι σε μηχανήματα εξυπηρέτησης στο εξωτερικό.

| Λεπτομερής περιγραφή προϊόντος | |||

|---|---|---|---|

| After-sale Provide: | Οι μηχανικοί είναι διαθέσιμοι σε μηχανήματα εξυπηρέτησης στο εξωτερικό | ||

| Product Name: | Automatic Pharmaceutical Cartoning Machine | ||

| Τύπος: | Vertical Cartoning Machine | ||

| Production: | 30-120 Κουτιά/λεπτό | ||

| Size Range Of Carton: | L(65-150)*W(35-85)*H(12-45)mm | ||

| Carton Weight: | 250-350σολ/?Ο | ||

| Function: | Cartoning Box Packing Machine | ||

| Αποκορύφωμα: |

high speed packaging machines, automatic capsule filler |

||

Fully Automatic Carton Box Packaging Packing Cartoning Machine Convenient Maintenance And Repair

| Λεπτομερής περιγραφή προϊόντος | |||

|---|---|---|---|

| Spare Parts Name | Specification | Manufacture | |

| Servo Motor | 400W MHMD042G1U | Panasonic | |

| Main Motor | R17DT80N4 1.1KW/220V/380V | SEW | |

| Frequency Converter | FC-051P1K5S2E20H | Danfoss | |

| PLC | Smart ST40 | Siemens | |

| Emergency Stop Button | ZB2-BE102C | Schneider | |

| Air Circuit Breaker | DZ47-D63/2P | Yaohua | |

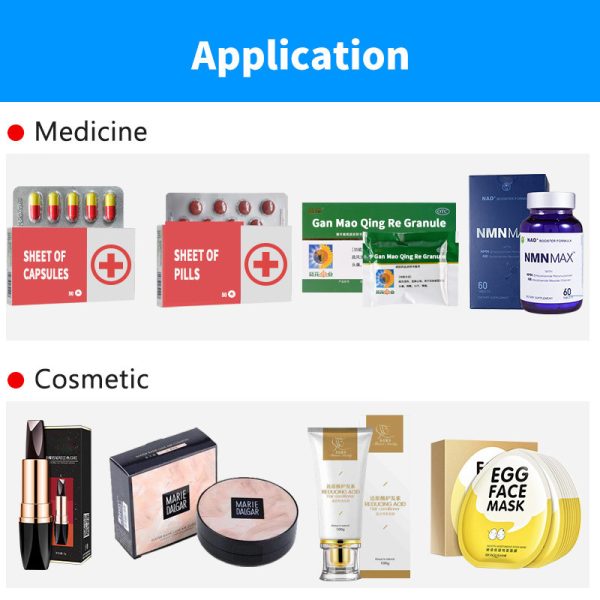

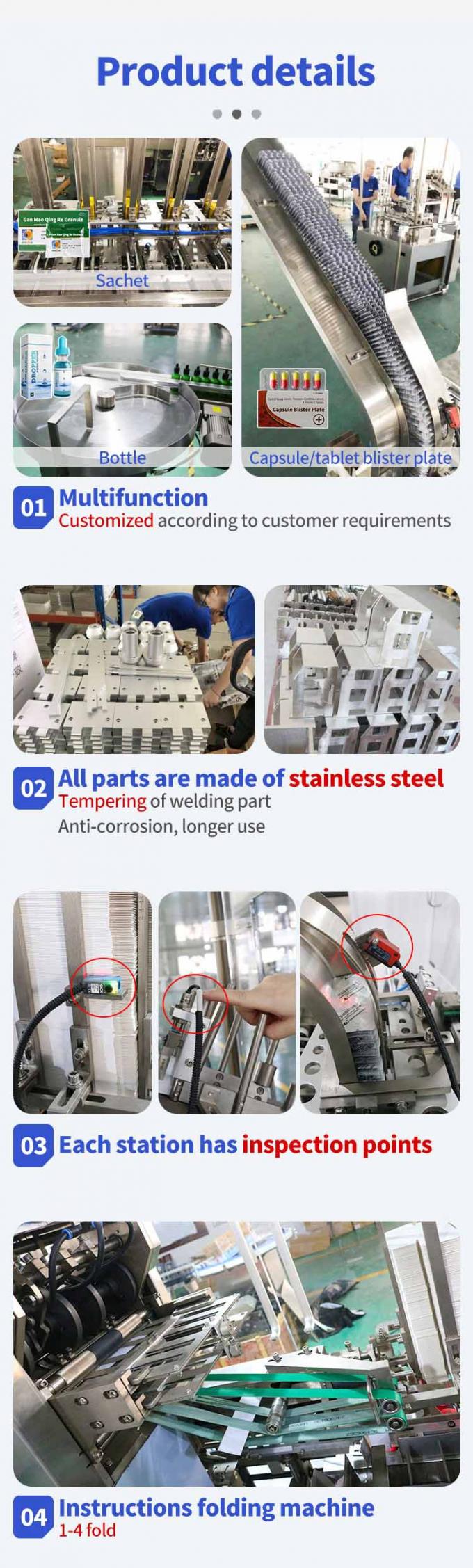

Λεπτομέρειες προϊόντος:

Production workshop:

On-site debugging:

About us:

Features:

1. The feeding part of machine adopts double servo motor,speed up to 120 carton/min,compared with single servo motor,it has fast speed and stable operation.

2. Dual clutch design, when the main motor overload or folding machine failure, start protection function to ensure the safety of equipment and personnel.

3. Detection points are densely distributed in various workplaces, such as feeding, quantity detection , packaging into conveyer belt, number of packages, carton in place and so on.