Automatische Kapselfüllmaschine 228000 Pieces Per Hour 000-5 Capsule NJP-3800D

Detailed Product DescriptionCapacity Max:228000 Capsules/hourApplication:Leistung??Körnchen??pelletCapsule Filling Rate:Above 99%Power:10.5KW (380V Or 220V Or 110V 50Hz)Automatic Grade:AutomaticUsage:Capsule ProductionApplicable Capsules:000/00/0/1/2/3/4/5Lärm:Machine Size:1500??1200??2200mmCore Componen…

- Voraussichtliche Lieferung : 7 Tage schnelle Lieferung

- Zertifizierung : CGMP CE ISO SGs usw.

- After-Sales zur Verfügung gestellt : Ingenieure für Service -Maschinen in Übersee zur Verfügung stehen.

| Detaillierte Produktbeschreibung | |||

|---|---|---|---|

| Capacity Max: | 228000 Capsules/hour | ||

| Application: | Leistung??Körnchen??Pellet | ||

| Capsule Filling Rate: | Above 99% | ||

| Leistung: | 10.5KW (380V Or 220V Or 110V 50Hz) | ||

| Automatic Grade: | Automatic | ||

| Usage: | Capsule Production | ||

| Applicable Capsules: | 000/00/0/1/2/3/4/5 | ||

| Lärm: | <75DB(A) | ||

| Machine Size: | 1500??1200??2200mm | ||

| Core Components: | Imported | ||

| Highlight: |

Automatische Kapselfüllmaschine, 228000 pcs/hour Capsule Filling Machine, 000-5 Kapselfüllmaschine |

||

NJP-3800D Automatic Capsule Filling Machine

1. Exceptional Versatility and Precision

Feature: The NJP-3800D can fill powders, granules, and other materials into various sizes of hollow capsules (000 to 5), with an accurate loading error of ≤3%.

Advantage: This machine ensures precise dosing and high flexibility in handling different types of filling materials and capsule sizes.

Benefit: Enhance your production capabilities by efficiently accommodating a wide range of pharmaceutical and health product formulations, reducing material waste, and ensuring product consistency.

2. Advanced Safety and Compliance

Feature: Equipped with safety features such as door control and emergency stop switches, and meets all GMP requirements.

Advantage: Comprehensive safety mechanisms protect operators and maintain a clean, compliant production environment.

Benefit: Operate with confidence, knowing your machine prioritizes worker safety and adheres to strict industry standards, boosting trust and compliance with regulatory bodies.

3. Innovative Pneumatic Blanking and Sealing

Feature: Utilizes a new pneumatic blanking system for materials with poor fluidity and features an imported SIL silicone rubber sealing ring for excellent dust prevention.

Advantage: Ensures smooth and dust-free operation, even with challenging materials, while maintaining superior sealing performance.

Benefit: Achieve a cleaner work environment and reduce the risk of contamination, ensuring the purity and quality of your capsules.

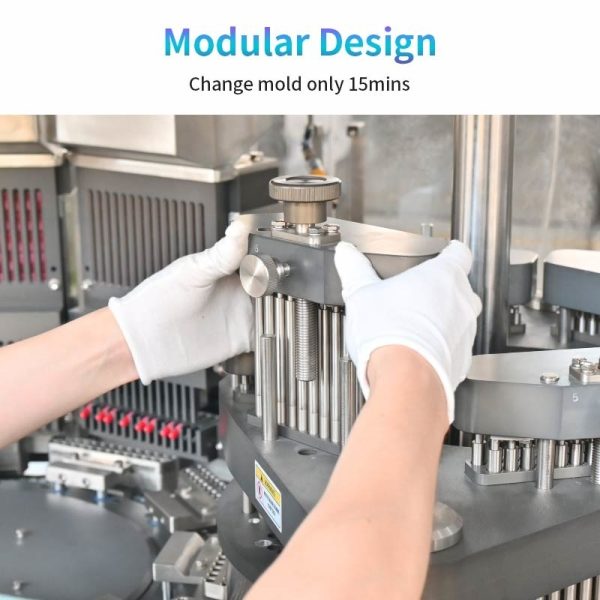

4. Simplified Maintenance and Modular Design

Feature: The NJP-3800D features a modular structure with easily disassembled components and a patented rotary design for quick maintenance.

Advantage: Maintenance and cleaning are straightforward, requiring minimal downtime, and mold changes can be completed in just 15 minutes.

Benefit: Minimize operational interruptions and maximize productivity, allowing for continuous 24-hour production cycles with ease.

5. Cutting-Edge Control and Efficiency

Feature: Equipped with a high-precision cam indexing box, SIEMENS HMI, and a three-dimensional adjustable filling mechanism with a powder recovery device.

Advantage: This setup ensures stable operation, precise filling adjustments, and real-time monitoring with minimal error and waste.

Benefit: Increase your production efficiency and product quality while reducing operational costs and waste, ensuring optimal

economic benefits and high output rates of up to 228,000 capsules per hour.

Der NJP-3800D Automatic Capsule Filling Machine is designed to revolutionize your capsule production process with its unmatched versatility, advanced safety features, innovative technology, ease of maintenance, and superior control systems. Elevate your manufacturing efficiency and product quality today with the NJP-3800D.

| Detaillierte Produktbeschreibung | |||

|---|---|---|---|

|

How to Contact Us? |

|||

|

|

Manager@richpacking.cn | ||

|

WhatsApp & Wechat |

+86-138-2609-3596 | ||

|

Visit WebSite |

www.richpacking020.com | ||