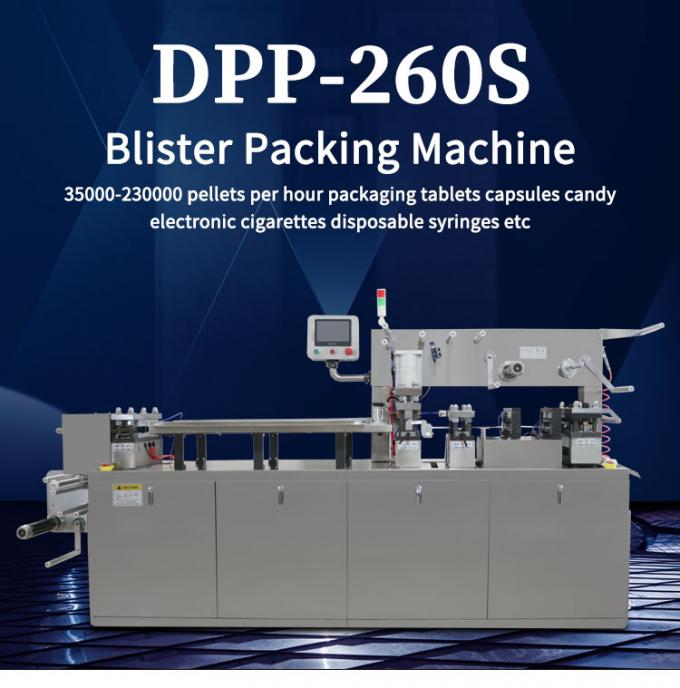

Dpp 260 Pharma Small Capsule Blister Packaging Machine Plastic Blister Pack Sealing Machine

وصف مفصل للمنتج الإنتاج:2400-9600 الكريات في الساعة. تشكيله. والعمق:240*170*15مم ماكس. عمق 26 مم??custom-madeBlanking:45 Times/minPower Of Main Motor:1.5kWTotal Power:6.2لوحة Kwstandard:80*57نطاق السفر MMStandard:40??185mmnoise:تسليط الضوء:Capsule Blister Packaging M…

- التسليم المقدر : 7 أيام التسليم السريع

- شهادة : CGMP CE ISO SGS وما إلى ذلك

- بعد البيع المقدمة : المهندسون المتاحون لآلات الخدمة في الخارج.

| وصف المنتج التفصيلي | |||

|---|---|---|---|

| القدرة الإنتاجية: | 2400-9600 الكريات في الساعة | ||

| الأعلى. تشكيله. والعمق: | 240*170*15مم ماكس. عمق 26 مم??مصنوع بطريقة مخصصة | ||

| طهي: | 45 مرات/دقيقة | ||

| قوة المحرك الرئيسي: | 1.5KW | ||

| القوة الكلية: | 6.2KW | ||

| لوحة قياسية: | 80*57مم | ||

| نطاق السفر القياسي: | 40??185مم | ||

| ضوضاء: | <75dBA | ||

| تسليط الضوء: |

Capsule Blister Packaging Machine, 185mm Blister Pack Sealing Machine |

||

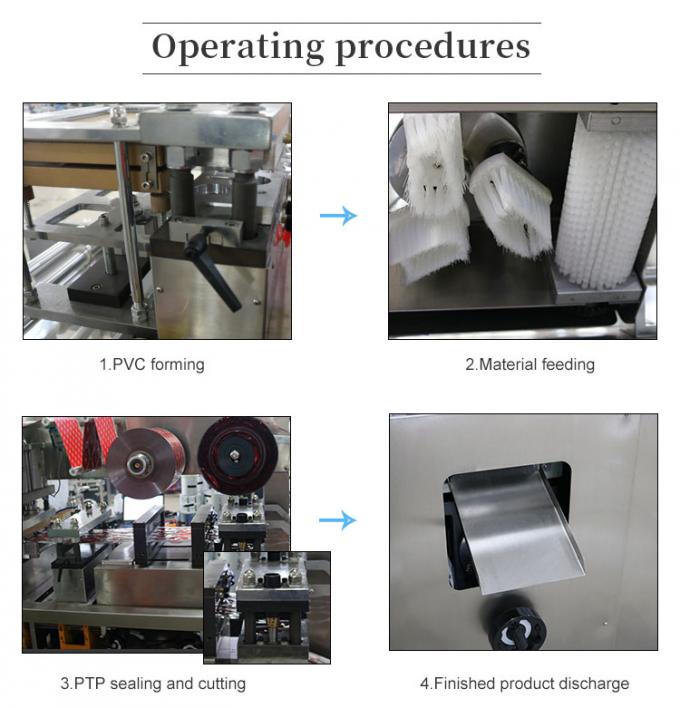

DPP-260S is a high-speed flat-panel aluminum-plastic blister packaging machine newly developed by Guangdong Rich Packing Machinery Co.,Ltd. It is driven by servo motor, with better accuracy, stable operation and convenient adjustment.DPP-260S expect can packaging tablets,capsules,حلوى,also can packaging many big sizes products,such as electronic cigarettes,perfume,tomato paste,soft capsules,big honey pills,penicillin bottles and etc.

| وصف المنتج التفصيلي | |||

|---|---|---|---|

| اسم | Spec./Model | Qty | Manufacturer |

| Servo Motor | 750WMHMD042G1U+MBDHT2510 | 1 | Panasonic |

| Adjusting Speed Plate | EM232CN | 1 | Siemens |

| Touch screen | ST700 | 1 | Siemens |

| Air circuit breaker | C65N-20A/3P | 1 | Schneider |

| Air circuit breaker | C65N-10A/1P | 2 | Schneider |

| Air circuit breaker | C65N-6A/1P | 1 | Schneider |

| Main motor | CH32 ZHP1500W | 1 | Taibang |

| Frequency inverter | DVA-3S0015G | 1 | Leader |

| Machine control valve | VM230-01-01 | 1 | Japan SMC |

| Cylinder | SSA φ32×15 | 2 | TAC |

| Programmable PLC | CPU224CN | 1 | Siemens |

| Solenoid valve | SG4V210-08 | 3 | TAC |

| Temperature Module | EM231CN | 1 | Siemens |

| Feeder motor | 802YT52 J15 | 1 | Taibang |

| Receiving and discharging motor | 4GN-15-K | 2 | Taibang |

| Formed heating plate | 170×130×20 | 2 | Rich Packing |

| Heat Seal Heating Plate | 158×110×20 | 1 | Rich Packing |

| Intermediate relay | MY2NJ | 5 | Omron |

| Thermocouple | WRKT-01 | 2 | Taishi |

| Solid state relay | SSR-40DA | 2 | Yangming |

| Cursor version | RQ-GB-3 | 1 | Yatai |

| Control transformer | JBK3-63 | 1 | Zhengtai |

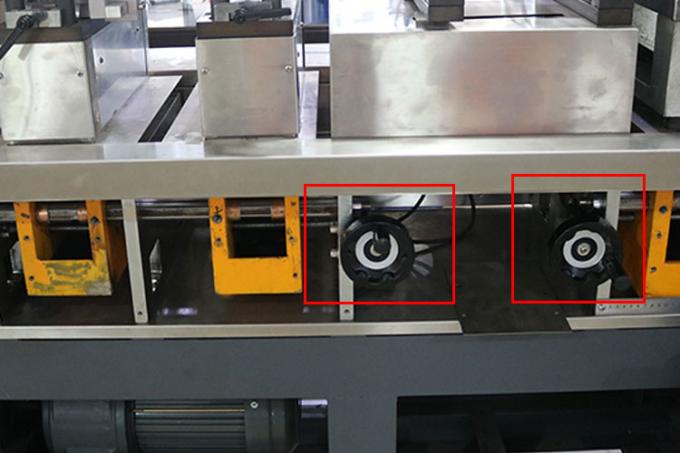

1.Servo traction motor

The blister pack sealing machine is driven by full servo, the traction distance is zero error, and the maximum traction distance can reach 185mm. It is suitable for long-term operation, easy to adjust and greatly reduces the difficulty of adjustment.

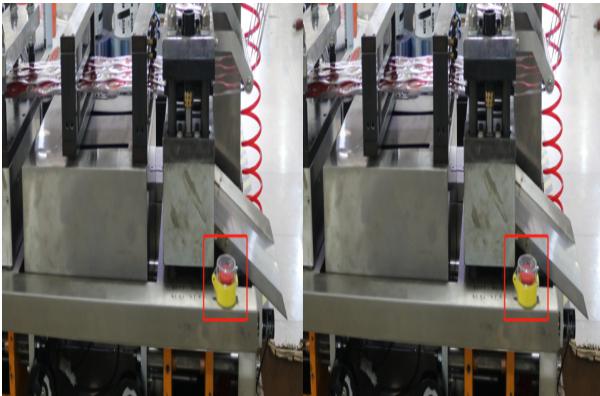

2.Cylinder Drive Heat Sealing Device

the blister pack sealing machine Adjustable temperature, Accurate Travel??Tight Sealing, No Wrinkles

3.Handwheel With Scales

Each Station Can Move Freely On The Spindle Through The Free Adjustment Of Handwheel

4.Locating Slot Pins Mould

One-key Positioning, And The Debugging Time Was Reduced 50%

5.Dual emergency stop protection

Because of the long size of 260S aluminium plastic blister packaging machine, there are two emergency stop devices, which can stop immediately in case of emergency.